Thorough Equipment Selection Guide for Wood Pellet Plant Setup

Establishing a complete wood pellet production plant requires meticulous planning, especially when it comes to selecting the equipment since it is closely related to the investment cost of a wood pellet plant setup. The success of a commercial or industerial wood pelletizing plant hinges on the efficiency, reliability, and capacity of the equipment installed. Here, GEMCO delves into key considerations and provides detailed information that addresses the concerns of customers interested in setting up a wood pellet plant.

Professional Guide on How to Choose Wood Pellet Production Machines

Complete wood pellet production process involves transforming raw wood materials into cylindrical pellets. common used raw materials for wood pellets production have sawdust, shavings, and more.

The type of raw material determines processes necessary for biomass pellet production. Wood pelletizing process typically includes: raw material preparation, size reduction through grinding or chipping, drying to reduce moisture content, pelletizing using a wood pellet machine. Afterward, the pellets are cooled, screened to remove fines, and finally stored or packaged for distribution. Biomass pelletizing process enables efficient utilization of biomass materials, providing a sustainable and clean energy alternative to fossil fuels. Below introduce equipment that may use in every wood pelletizing process.

Raw Material Handling before Pelletizing

Efficient handling of raw materials is crucial for smooth operations of a wood pellet plant. Consider the following factors when selecting equipment for raw material handling:

- Conveyors: Opt for belt conveyors or screw conveyors that can handle various biomass materials. Consider the conveying capacity, power requirements, and the ability to handle materials of different sizes and moisture content.

- Debarkers: If using whole logs as raw material, debarkers can efficiently remove the bark. Look for debarkers that minimize wood loss, reduce energy consumption, and are suitable for different log diameters.

- Shredders and Chippers: These machines reduce the size of raw materials and ensure uniformity. Choose shredders and chippers based on their throughput capacity, energy efficiency, and ability to handle various wood waste or byproducts.

Drying - Key Process to Reduce Operation Cost

Proper drying of raw materials is essential to achieve optimal pellet quality. Consider the following aspects when selecting drying equipment:

- Dryer Types: Rotary dryers and flash dryers are commonly used in wood pellet plants. Evaluate their energy efficiency, drying capacity, ability to handle different biomass materials, and maintenance requirements.

- Moisture Control: Look for drying systems with precise moisture control mechanisms to achieve the desired moisture content for pellet production.

- Heat Source: Consider the availability of fuel sources like biomass, natural gas, or waste heat, and choose a dryer that aligns with the available resources and offers cost-effective operations.

Size Reduction

Efficient size reduction ensures uniformity in pellet size and density. Consider the following factors when selecting size reduction equipment:

- Hammer Mills: Opt for hammer mills that offer high capacity, low energy consumption, and the ability to produce consistent particle sizes.

- Grinders: Depending on the raw material characteristics, grinders may be a suitable alternative to hammer mills. Evaluate their capacity, power requirements, maintenance needs, and ability to handle different materials.

- Screening: Incorporate screening equipment to remove oversize particles and ensure consistent particle size distribution. Look for screens that provide accurate and efficient separation.

Pelletizing - Core Sections in a Wood Pellet Plant

Pelletizing is a critical process where the raw material is compressed into pellets. Consider the following aspects when selecting pelletizing equipment:

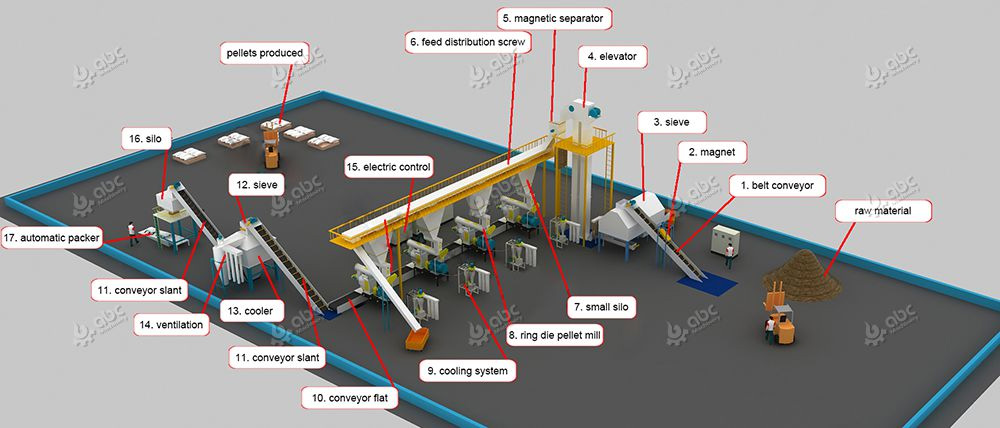

Equipment Layout in a Complete Wood Pellet Factory

- Pellet Mills: Choose biomass pellet mills based on their capacity, energy efficiency, die and roller durability, ease of maintenance, and ability to handle different biomass materials.

- Die and Roller Design: Opt for high-quality dies and rollers that minimize wear and enhance pellet quality and production efficiency.

- Conditioners: Depending on the raw material, consider the use of conditioners to improve pellet durability and reduce fines generation.

Cooling and Screening to Ensure Good Pellets

After pelletizing, the pellets need to be cooled and screened for optimal quality. Consider the following factors for cooling and screening equipment:

- Pellet Coolers: Look for coolers that offer efficient cooling rates, controlled pellet temperature, and the ability to handle high pellet throughput.

- Screening and Sieving: Incorporate vibrating screens or rotary screens to remove fines and ensure consistent pellet size. Consider their accuracy, capacity, and ease of maintenance.

Storage and Handling

Efficient storage and handling equipment are vital to maintain pellet quality. Consider the following factors:

- Silos and Storage Bins: Select silos or storage bins that provide proper ventilation, protect against moisture ingress, and facilitate smooth pellet flow.

- Conveyors and Bucket Elevators: Opt for robust conveyors and bucket elevators to transport pellets between different stages of production. Consider their capacity, power requirements, and compatibility with pellet characteristics.

- Packaging and Bagging: Depending on the intended market, choose appropriate packaging and bagging equipment to ensure the safe storage and transportation of pellets.

Quality Control of Final Pellet Product

To maintain consistent pellet quality, incorporate quality control equipment into your plant design. Consider the following:

- Moisture Meters: Install moisture meters to monitor and control the moisture content of the pellets.

- Pellet Durability Testers: Utilize durability testers to assess pellet strength and resistance to breakage.

- Sieving Equipment: Use sieving equipment to check pellet size distribution and remove fines or oversized pellets.

Biomass pellet production machines and processes depend mainly on the raw material used. If the raw material is sufficiently dry and the particle size is sufficiently small, then the pelletizing process becomes the simplest case, i.e., only the pelletizing itself and the subsequent cooling. But, if the raw materials is large and contains much moisture, equipment to reduce size and remove moisture are necessary. Therefore, if you have no idea how to choose the suitable equipment for your wood pellet plant, just contact our professional engineers.

Wood Pelletizing Plant Turnkey Project Undertook by GEMCO

With a strong reputation for reliability and excellence, GEMCO is your go-to supplier for high-quality wood pellet equipment. Our wood pellet manufacturing machines are designed for optimal performance, ensuring consistent and efficient pellet production. What sets GEMCO apart is our comprehensive approach – we offer complete wood pellet plant solutions tailored to your specific needs. From initial design and installation to ongoing support and maintenance, we are committed to your success. Up to now, we have built wood pellet plant around the world, such as Italy, Morocco, Indonesia, Philippines, Vietnam, South Korea, Australia, Ghana, United Kingdom, Portugual, Chile, Canada, and more. If you are interested in knowing more, very welcome to contact us anytime!