DIY wood pellets with homemade pellet mill

"Can I make my own wood pellets at home? Yes, of course you can." DIY wood pellets at home is a practical skill that is both environmentally friendly and economical. By converting waste wood into efficient pellet fuel, you will not only reduce your energy bills, but also the burden on the environment. Additionally, wood pellets can be used for a wide range of purposes, such as barbecuing, cooking, and heating. If you are interested in the process of producing homemade wood pellets, this article will show you how to make your own wood pellets easily at home. (Read More About Turn Sawdust Into Heat>>)

Wood Pellet Combustion

To enable you to easily make your own wood pellets at home, in this article, we will introduce the key steps and important considerations for making wood pellets at home, ensuring your successful pellet production. This project will offer you satisfaction and tangible benefits. Now, let's get started together!

An Introduction to DIY Wood Pellet Production at Home

| Preparation of DIY Wooden Pellets | |

|---|---|

| Raw Materials | Wood, branches, leaves, etc. |

| Machinery and Equipment | (hammer mill), Flat Die Pellet Mill |

| Safety Preparations | Gloves, protective glasses, protective clothing, etc. |

| Other Tools | Axe, chainsaw, hygrometer, moisture-proof bag, etc. |

Homemade Wood Pellet: Easy Steps

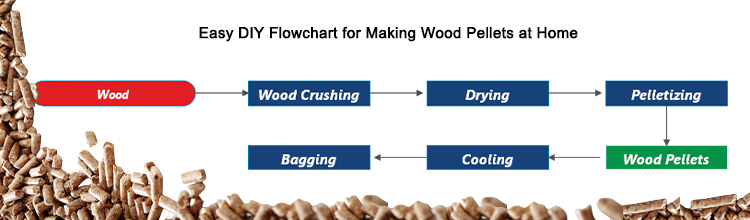

Simple Flowchart for Homemade Wood Pellet Production at Home

- Preparing Raw Materials

When making wood pellets at home, the availability of the raw materials chosen is crucial. Some of the raw materials that are easily available for making wood pellets at home are wood, sawdust, wood shavings, peanut shells, hay, twigs and leaves. In addition to this, old furniture, paper shavings, and wooden bags can also be utilized for making wood pellets by wood pellet press machine.

Raw Materials for the Production of Wood Pellets

For different raw materials also need to adjust the different parameters of the Home Pellet Mill. If you have any questions about raw materials, consult us for free!

- Crushing Raw Materials

Raw materials are generally required in sizes from 6 mm - 25 mm. At home, axes and chainsaws are useful for handling unusual raw materials. For convenience. You can also buy crushed raw material from the market or opt for twigs and leaves that require simple pre-processing. If you are on a budget, you can buy a hammer machine to help you crush larger raw materials into smaller sized chips.

- Drying the Raw Material

Before making wood pellets, the crushed raw material needs to be left in the sun for at least 24 hours to dry it. This step is crucial and requires reducing the moisture content in the raw material. In general, the moisture content of raw materials is controlled at 8% - 12%. If you skip this step, the quality of the particle will be seriously affected.

- Pellet Making Process

In homes, wood pellets are often used as fuel. As a small pellet machine, the Flat Die Pellet Machine is the most used wood stove pellet maker machine. Dry raw material is put into the wood pellet maker machine, the rollers of the wood mill and the flat mold exert tremendous pressure and generate frictional heat. Under the pressure of the pellet mill rollers, the raw material is compressed and begins to flow out of the holes in the flat die. The compressed pellets are then processed by a knife or cutter and are cut into small pellets.

Homemade Pellet Making Machine

Flat die pellet making equipment is more suitable for wood pellet machine due to its low price and small output.

- Structure of Flat Die Pellet Maker: It consists of different parts such as feed hopper, grain outlet, mold, roller, cutter, motor, control cabinet, wheels and so on. (Ask a PDF of Flat Die Pellet machine Structure Design>>)

- Types of Flat Die Pellet Making Machine: In order to be more suitable for home use, it can be divided into electric pellet mill, diesel wood pelletizer, PTO pellet machine and gasoline pellet maker according to different power.

- Price and Output of Flat Die pelletizer: The price is as low as 500 US dollars, and the output is 60-1000kg/h. (Link to Buy A Cost-Effective Wood Pelletizer Machine Online>>)

- Pellet Cooling and Storage

Pellets coming out of the wood pellet making machine have high temperature, in order to reduce the temperature, we need to scatter them over a larger area to dissipate the heat. At the same time, if conditions permit, a pellet cooler machine can be used to cool these hot pellets. Once the temperature is lowered, we can place them in plastic or paper bags for future use.

Safety Notes for DIY Wood Pellet Production and Usage at Home

Making and using wood pellets is a rewarding activity, but care must be taken and safety is always a priority. If you are unsure how to perform it correctly, seek professional advice. Safety is always a priority.

- Choose Safe Raw Materials: Using raw materials that are free of paint, glue and toxins is essential to the quality of wood pellet fuel and to your health.

- Wear Protective Equipment: Wear appropriate protective equipment to prevent wood chips, dust, and other particles from contacting your skin and eyes.

- Select Appropriate Tools: Use appropriate tools and avoid unstable workbenches.

- Operate Machine as Specified: Follow manufacturer's recommendations and guidelines closely to ensure safe operation of equipment.

- Observe Fire Safety: Store pellets away from open flames and hot areas to prevent accidental fires. Ensure that suitable fire extinguishing equipment is nearby.

- Ensure Good Ventilation: Ensure good ventilation when making pellets and using them to reduce the risk of carbon monoxide and harmful gases.

- Storage Requirements: Store wood pellets in a dry, well-ventilated area to prevent mold and moisture. Keep away from children and pets. Avoid piling up too many pellets in the home to reduce the risk of fire.

Although making wood pellets may seem simple, it still requires some specialized knowledge and skillful guidance. If you want to increase your probability of success, I sincerely suggest you seek help from professionals. And we can provide you with free professional answers and advice. Whether you are a beginner or an experienced wood pellet maker, we are willing to share our knowledge and happy to provide you with answers to whatever questions you may have about making wood pellets. There is no need to hesitate to contact us for free!

Buy Mini Homemade Pellet Machine to Make Wood Pellet

How to Make Pellets at Home? How to DIY your own wood pellets at home by buying a homemade pellet maker machine at factory price? How to get free instructions for making your own wood pellets for stove pellets? Contact us for FREE to start your processing wood pellet plan now! GEMCO's high-quality low-priced wood pellet production machine has been exported for over 30 years to countries around the world, such as the United States, Czech Republic, Guatemala, South Korea, Japan, Thailand, Indonesia, etc.