[Brazil] Affordable Biomass Pellet Machine Prices for Increased Profit

Brazil, with its abundant agricultural resources and supportive government policies, is rapidly developing its biomass pellet industry, becoming an integral part of renewable energy production. The demand for biomass pellets is steadily growing due to the promotion of co-firing policies, attracting significant biofuel production investments. This article explores the prospects of Brazil's biomass pellet market and introduces GEMCO’s efficient biomass pellet production equipment and customized solutions to help investors succeed in Brazil.

Wood Biomass Pellet Machines Price in Brazil

Brazil Biomass Pellet Market Analysis

Driven by policy incentives and market demand, Brazil’s biomass pellet market has seen significant growth in recent years. According to data from Brazil's National Energy Research Agency (EPE), by 2022, biomass energy accounted for 9% of Brazil's total electricity capacity, becoming a key component of the country’s clean energy portfolio. As an efficient alternative fuel, Brazilian biomass pellets are gaining increasing attention, with growth fueled by both policy incentives and Brazil’s rich agricultural resources.

- Abundant Raw Material Supply

Brazil’s agricultural resources provide a steady and affordable supply of raw materials for biomass pellet manufacturing plants. For instance, the country produces over 700 million tons of sugarcane annually, and the bagasse generated during sugarcane processing serves as an ideal raw material for bagasse pellet machines in Brazil. Additionally, sawdust and other agricultural waste are important sources of raw materials, significantly lowering production costs for biomass pellet processing plants.

Complete Sugarcane Bagasse Pellets Production Line for Sale

Brazil’s sugarcane bagasse pellets, along with other agricultural residues like sugarcane pellets, are becoming key components of the country's biomass energy system, reducing reliance on coal. GEMCO’s biomass pelletizer equipment is designed to handle various raw materials like sugarcane bagasse pellets, making the biomass pellet production process more efficient and cost-effective.

- Policy Incentives

The Brazilian government has launched several policies supporting bioenergy, further driving the development of the biomass pellet manufacturing industry. These include green energy auctions, tax reductions, and subsidy policies that provide financial support to Brazilian biomass pellet plant operators. These initiatives not only increase the market demand for biomass fuel pellets but also create an attractive investment environment for biomass pellet producers.

Impact of Biomass-Coal Co-firing Policy on Biomass Pellet Plant Project Investment

Starting in 2024, Brazil’s implementation of the biomass-coal co-firing policy is set to increase demand for biomass fuel pellets, enhancing the attractiveness of biomass pellet manufactuirng plant investments in the country.

- Demand Surges in Biomass Pellet Market

This policy mandates that some coal-fired power plants gradually increase the proportion of biomass fuels they use. According to predictions from Brazil’s National Electric Energy Agency (ONS), biomass pellet demand in Brazil is expected to reach 5 million tons by 2024, creating enormous market opportunities for biomass pelleting plant investors. This increase in demand directly impacts the biomass pellet manufacturing process, providing investors with a lucrative biomass pellet business opportunity.

- Increased Profitability for Biomass Pellet Manufacturers

Biomass power generation costs have significantly decreased. According to Brazil's Ministry of Energy, the cost of biomass electricity generation in 2023 was approximately $60 per MWh, lower than traditional coal power generation costs. This economic advantage makes Brazilian biomass pellet production plant investments attractive, with stable return on investment (ROI) expectations.

- Stable Policy Environment

Government auction policies ensure the price stability of Brazilian biomass pellets, especially in high-demand regions like the North and Midwest, reducing investor risk. The stability of biomass pellet prices in Brazil plays a vital role in attracting investors to the biomass pellet production manufacturing sector, especially those involved in wood pellet manufacturing plants.

Biomass Pellet Machines Price in Brazil for Biofuel Plant Investment

When investing in a biomass pellet production line in Brazil, the main factors include biomass pellet machine price, raw material costs, site fees, labor cost, and operating costs. (Read more about Guide to Start Wood Pellet Plant>>) Here's a detailed breakdown:

Pellet Equipment Investment Costs

The core of investing in a Brazilian biomass pellet production machine lies in selecting the right biomass pellet press machine and related equipment. GEMCO offers various options for biomass pellet manufacturing machines, catering to different production scales.

Best Wood Pellet Manufacturing Machines in Biomass Pellet Mills

- Ring die pellet machines are suitable for large-scale production. Though the initial investment cost of biomass pellet machine of large biomass pellet processing line is higher, their high efficiency and low energy consumption allow for continuous 20-hour daily production, with payback typically occurring within 2 years.

- Flat die small pellet mills are ideal for medium and small-scale pellet production factories. They have lower initial investment costs, with payback within about 6 months, making them perfect for investors testing the market at a smaller scale biofuel pellet production.

The cost of biomass pellet equipment primarily depends on the production scale, and GEMCO’s biomass pellet production line in Brazil can be custom-designed according to specific production needs, helping investors maximize cost-effectiveness. GEMCO’s biomass pellet mill is designed for various scales, including small-scale setups, helping investors achieve flexibility in production.

Raw Material Costs

Brazil’s abundant agricultural waste provides cheap and ample raw material. GEMCO’s equipment can handle up to 50 different biomass materials, including sugarcane bagasse pellets and other agricultural residues, and uses modular design to increase raw material utilization efficiency, helping investors reduce raw material wastage.

Site and Construction Costs

The costs for building a biomass pellet production plant in Brazil vary by geographic location. In general, land leasing and construction costs are relatively low, especially in rural areas with high resource concentration. GEMCO’s equipment features modular and compact designs, reducing space requirements and making site costs more manageable.

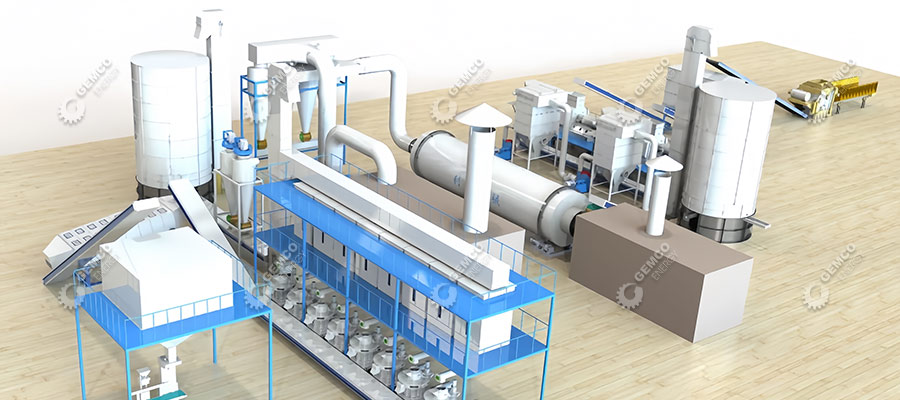

Biomass Pellet Processing Plant Layout Design

Additionally, installation and commissioning costs should be considered. GEMCO offers one-stop services, including 3D plant design of biomass pellet plant, equipment installation, and on-site commissioning, which helps reduce extra costs and time during the installation process. This integrated service model significantly lowers the overall biomass pellet plant project report costs.

Labor Costs

Labor costs in Brazilian biomass pellet plants are mainly related to equipment operation, maintenance, and raw material handling. GEMCO’s biomass pellet machinery supports automated operations and comes equipped with automatic lubrication and smart control systems, reducing reliance on manual labor. This not only lowers labor demands but also reduces biomass pellet plant operational costs.

Furthermore, GEMCO provides comprehensive training and technical support to help local employees get up to speed quickly, further reducing labor costs.

Brazil’s growing biomass pellet market offers significant investment opportunities, especially with the government's favorable policies and the increasing demand driven by co-firing initiatives. GEMCO provides high-efficiency biomass pellet machines, customized solutions, and comprehensive support to ensure that investors can succeed in Brazil’s biomass pellet industry. If you need any help, you can ask below and our team of professionals will provide you with a free answer within 24 hours.