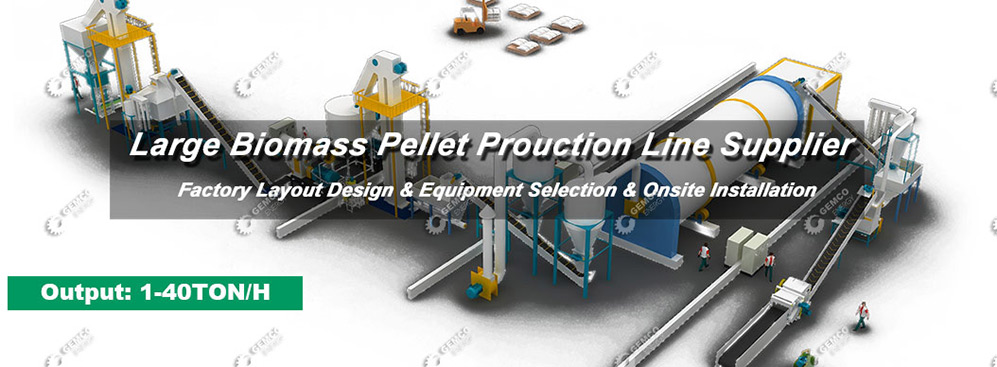

large pellet production line

Large pellet production line refers to a complete biomass pellet mill plant with a production capacity of more than 1ton/h. GEMCO, with at least 20 years of experiences in biomass pelletizing industry, can provide turnkey solutions for biomass pelletizing from various raw materials. The designs or plans for wood pellet plant provided by us will be flexibly customized based actual requirements. Welcome contact us directly to get more information!

Factory Layout Design of Large Wood Pellet Production Line

Setup a Large Pellet Production Plant at Low Cost

Although the market demand for biomass pellets as fuel keeps rising repidly, it is also very important to a have a complete study on biomass pellet manufacturing industry and how to set up a large pellet production plant at reasonable cost. Here are some simple guides should be noted if you are interested in biomass pelletizing business: conduct a feasibility study and market analysis, assess raw material availability and cost, understand regulatory requirements, choose cost effective pellet processing equipment, plan storage and handling facilities, consider transportation logistics and distribution channels and more. (Read more: Biomass Pellet Project Cost >>)

Raw Material for Large/Commercial Pellet Production Business

Large pellet production lines, designed by GEMCO, can be used to make various raw materials into biomass pellets for fuel. The most frequently used raw materials for large pellets production line are wood, sawdust, EFB (palm fiber), bamboo, coconut shell, bagasse, and other agricultural waste, etc. (Read more: How to Make Pellets from Various Biomass Materials?)

Various Biomass Materials for Pellets Production Business

Large/Industrial Biomass Pellet Production Line Flow Chart

► Wood Pellets Production Process: Biomass Materials Crushing → Drying → Pelletizing → Cooler → Packaging Machine;

► Machines Required for Large Pellets Production: Crusher → Conveyor → Large Dryer (not necessary if the raw material has a 12-18% moisture content) → Elevator → Silo → Ring Die Pellet Mills → Larger Cooler → Finished Products Warehouse → Automatic Weighting and Packaging System; (For more details about the components of the complete pellet line see biomass pellet plant. )

► Please Note: Above biomass pellets production process and wood pellet processing machines are not absolute, we will make a customized plan of large scale pellet mill plant according to your specific situation.

Large Pellet Production Project Report - GEMCO

Below shows some of the biomass pellet plant projects we built for our customers. Our large pellet production plant, with capacity of 0.5-10ton/h, is CE certified by SGS. If you are interested in how much would cost to set up a complete pellet production line, just contact us directly to get full project report on GEMCO biomass pellet plant projects!

GEMCO is your go-to professional supplier of biomass pellet machines, catering to all your wood pellet production needs, either for household use or commercial purposes. With our strong capacity and expertise, we excel in undertaking turnkey projects for large-scale or industrial wood pellet production plants. Our extensive experience in installation and commissioning ensures smooth and successful project execution. Having successfully completed many projects worldwide, we have established a global footprint and a solid track record of delivering high-quality wood pellet production facilities. We have built large pellet production line in different regions and countries, including UK, Australia, Canada, Portugal, Bulgaria, Serbia, Italy, Morocco, Hungary, Ghana, Nigeria, Korea, Indonesia, Malaysia, Philippines, Vietnam, Pakistan, and more.

We can provide comprehensive solutions tailored to your specific requirements. Trust GEMCO to deliver efficient and reliable wood pellet production systems that meet your production goals and adhere to the highest industry standards. Contact us today to discuss your project and benefit from our industry-leading expertise.