Fuel Pellets from Waste Processed by Biomass Pellet Mill

Nowadays, there are many kinds of wastes in our life, like life waste,industrial waste,wood waste, they not only affect our living environment, but also pollute environment, so finding a reasonable handling method to those wastes is vital to our environment. Biomass pellet mill can solve that problem and the biomass pellet mill takes the wastes as raw materials and processes them into fuel pellets from waste. Then how does the biomass pellet mill work? Let’s take wood waste as an example to know about it.Wood Waste Introduction

We all know that, wood waste has many kinds of types, for example, the furniture plant will produce lots of wood waste in the production, and the forestry will also produce lots of wood waste. The amount of the wood waste is huge, if they are not used reasonably, it will cause great damage to the environment and it is a waste to the energy. In the era of energy shortage, we should learn to make good use of the resources that the nature gives us.

Biomass Pellet Mill Introduction

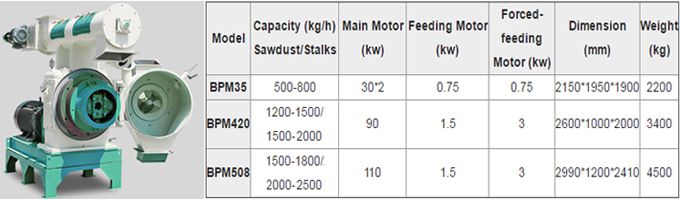

Biomass pellet mill is one kind of biomass machines in our company, and it can process the above materials into fuel pellets from waste. This kind of machine mainly uses high temperature and high pressure to turn the biomass raw materials into high-density, high-burning efficiency of fuel pellets from waste, which can be used in different areas like power station and other energy consumption units. The fuel pellets from waste can be also used in the fireplace, cooking stove, etc. Our company has different kinds of pellet mills for customer to choose, like ring die pellet mill, flat die pellet mill. If you want to produce pellets in large scale, we also have the whole production line for customer to choose.Fuel Pellets from Waste Processing Steps

Usually speaking, most of the wastes can not be processed by the biomass pellet mill directly, and they should be preheated. We need to crush the materials into small pieces that is suitable for the pellet mill processing size and the moisture content also should be control well, so the drying machine will be needed. After the size and moisture content are suitable, you can start to make pellets by using the pellet mill. Before making pellets, you should debug the pellet mill and make sure the pellet mill be in a good condition. The produced pellets need to be cooled by cooling machine then packed. The whole production process is over.Fuel Pellets from Waste Advantages

Compared with traditional fuels, fuel pellets from waste has the obvious advantages:We will take the following energy as an example: the needed energy to heat 1000kg of water from 20℃ to 60℃

| Energy | Needing amount | Unit price | Whole cost (yuan) |

|---|---|---|---|

| Light diesel oil | 4.5kg | 6.3 yuan/kg | 28.4 |

| Heavy oil | 5kg | 4.5 yuan/kg | 22.5 |

| Natural gas | 5.3Nm3 | 3.5 yuan/Nm3 | 18.5 |

| Biomass pellet fuels | 10.4kg | 1.0 yuan/kg | 10.4 |

Get In Touch

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel FREE to contact us!