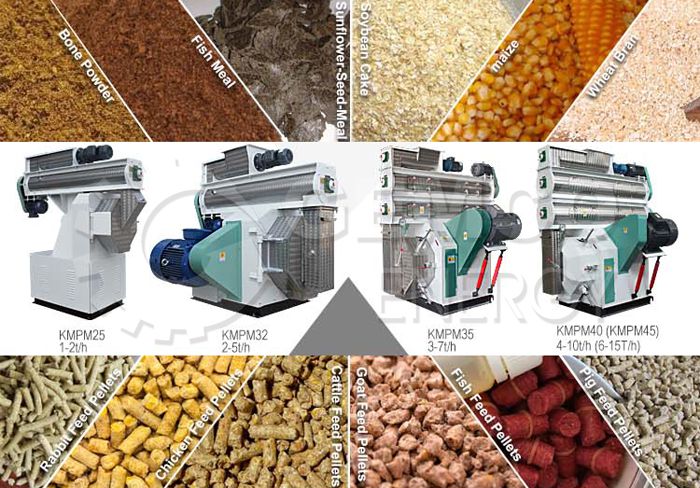

Professional Fodder Pellet Mill for Enriching Animal Nutrition

Basic Info for Fodder Pellet Mill

Fodder pellet mill is designed and developed for making feed for animals, adopting pelleting die and pressing roller to compress the loose raw materials into density pellet feed under the high temperature of the pelleting chamber. It's also called feed pelllet mill or feed mill. Various raw materials can be made into feed pellet, such as, corn, wheat, grass, grasses, pasture, soybean, straw meal, leftover, carrot, potato, cassava, rice, oil cake etc.

Classification of Fodder Pellet Mill

According to the different principle, the fodder pellet mill is divided into two big types, including flat die fodder pellet mill and ring die fodder pellet mill, the former adopts flat die while the die of latter is just like a ring, each of them has its own unique features.- Flat die type

- Ring die type

Fodder Pellet Production Details

At the first process, you need to prepare the raw material according to the nutrition demand of your animals, as we all know that different animals require different nutrition, even the same kind of animal, they have different nutrition demand in their different growing period.Before you start to make feed pellets, you should do some pre-preparation well, because the fodder pellet mill has a strict requirement for the raw material. The moisture content should be around 12%- 15%, and the size can not be larger than the diameter of die hole. If your raw material are not proper, you can choose the related machine for better production, like hammer mill, dryer and mixing machine.

After preparing the raw material well, it’s time to start the feed pellet production. Our fodder pellet mill types have been mentioned above, you can choose the proper one for your application. The fresh finished feed pellet has a high temperature, you should cool them before packing. If you make small scale feed pellet, you can put the pellets in a cooling place for self-cooling; if you make large scale fodder pellets, the cooling machine and packing machine are suggested to you for saving your time and proving the production efficiency.

Get In Touch

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel FREE to contact us!