Ring die pellet mill

Biomass pellet mills generally have two types. One is called a ring die pellet mill while the other is called a flat die pellet mill. Both vary in their design, working principle, production capacity, etc. however, both have the same function - biomass pellets production.

Biomass Materials and Biomass Pellets

Ring die pellet mill is the key component in a complete biomass pellet plant. It is mostly used to process wood materials like wood chips, sawdust, tree branches, logs, and so on, so it is a kind of large scale wood pellet maker. Also, it can process other raw materials like palm fiber, sugarcane bagasse, peanut shell, corn stalk, wheat straw and many other agro-wastes.After GEMCO Machinery has analyzed the cost and profit of the biomass pellet processing industry and the ring die pellet machine processing plant, it can be understood that the investment in the ring die pellet machine is very promising and there is also a profit margin. If you want to join the biomass pellet processing industry, or need to purchase a ring die pellet machine, you can contact GEMCO Machinery.

Ring Die Pellet Mill for Sale

Ring die pellet machine is usually used when you need a biomass pellet mill for large scale production. As it is used for large scale production of pellets, its price is higher than other type of pellet mill. The capacity of ring die pellet mill can be 500~2000kg/h.

Output of Small Ring Die Pellet Machine: 500-800kg/h

Output of Large Ring Die Pellet Machine: 1.2-2.5ton/h

To get detailed machine parameters, price list, spare parts and more, please feel free to contact us directly. Our professional technicans and sales are always here for you! Now, visiting our factory by remote video is available. And, we also provide pelletizing testing service for different raw materials. Any questions, please just contact us without any hesitation!

Why is the ring die pellet machine popular with investors?

- Good market prospects

Traditional energy can no longer meet the needs of the global market. Biomass pellet fuel, as a substitute for coal, can just make up for this energy gap.

- Sufficient source of raw materials

The annual output of biomass energy such as straw exceeds the total energy demand, and as a renewable resource, their reserves are very abundant. Therefore, it currently has a good market prospect as an energy source.

- High profit

The raw materials of the ring die pellet machine are crop stalks and so on. The cost of these materials is low, the cost per ton is low, and the processing output of the ring die pellet machine is high. In the face of huge market demand, the industry has considerable profits.

Working Principle of Ring Die Biomass Pellet Mill

A ring die pellet mill consists of several parts such as feeder, ring dies, rollers, motor, and discharge port. Raw material is fed into the pellet mill through a screw feeder from there it enters into the conditioner. In this part, an adherer, which helps in binding the particles together, is added and mixed with the raw material. It helps in forming dense and solid pellets.

From the conditioner, the raw material enters in the pelletizing region. This region has a ring-shaped die, thus this biomass pellet manufacturing equipment is called a ring die pellet mill. Two to four rollers are present inside the ring die. When raw material enters this chamber, centrifugal force pushes it on the inner side of the ring die. Usually, both roller and ring die rotate which presses the raw material in between two surfaces (one is of the roller and the other is of ring die).

Compressed raw material squeezes out of the holes of the ring die. When they come out of these holes they look like sticks. A knife-like slicer cuts these sticks and produces pellets of the desired size. Through it, you can change the length of pellets as per your needs. This is working process of a ring die pellet machine.

Working Video of Ring Die Wood Pellet Mill

Ring die pellet mill at factory price for sale: HOT sale ring die pellet machine offered by biomass pellet machine manufacturer or supplier, guide on process of pellets production and how to start biomass pellet manufacturing business with limited cost in Tanzania, Egypt, Morocco, Ghana, South Korea, etc.

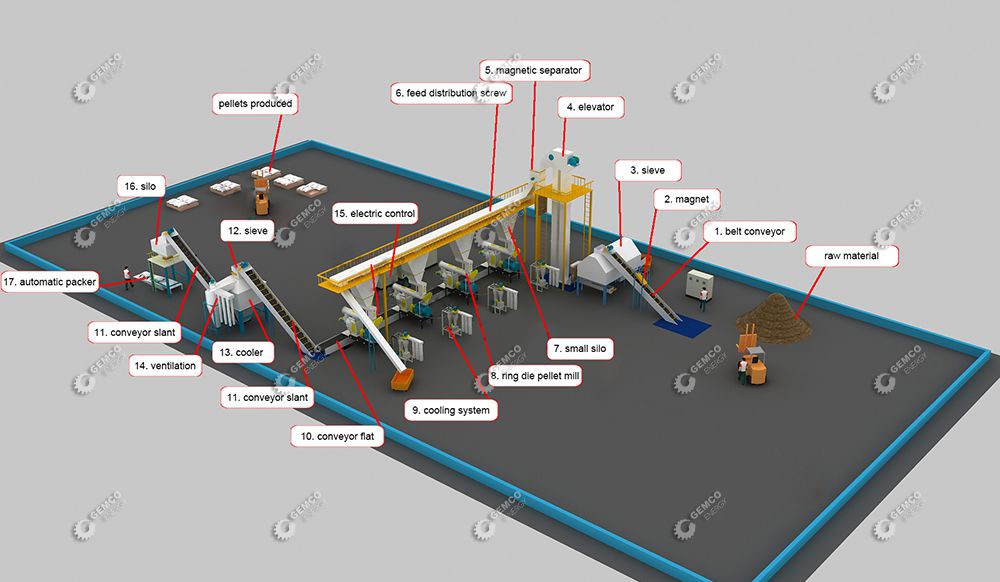

Buy Ring Die Pellet Machine to Set up Efficient Biomass Pellet Plant

According to the usages of biomass pellets, nowadays, biomass pellets are mainly used in biomass power generation plants, biomass boiler, household heating and other industrial sectors. Therefore, investing a biomass fuel industry by building a pellets manufacturing plant has huge market potentials.

With years of experience in biomass fuels, we are willing to provide consulting services for all kinds of biomass fuels and to help our customers solve problems in their biomass pellets production plant projects. We are the leading ring die wood pellet machine manufacturer in China and we are also have strong capacity to offer the auxiliary equipment in a biomass pellet factory. Just get in touch with us to get the latest price and technical parameters of biomass pellet processing equipment!

Advantages of Ring Die Pellet Mill over Flat Die Pellet Mill

Ring Die Wood Pellet Machine for Sale

- Larger Output: The production capacity of ring die pellet mill is relatively large and is more suitable for industrial pellet production

- Superior Pelletizing Capability: It can process very wide range of biomass materials, especially the hard wood materials, like palm fiber.

- Higher Quality Pellets: The pellets made by ring die pelletizing machine have larger density and is much smoother surface due to its higher pressure.

It can be seen that the ring die pellet machine has better advantages in the production of biomass pellets; if you have higher requirements for the compression ratio and appearance of the pelletized products, and you also need equipment with higher production efficiency and output, it is recommended that you choose the ring die pellet machine. If you only need a small single pellet machine to develop a smaller-scale production business, you can choose the flat die pellet machine, which may be more suitable for you.

Calorific Value of Biomass Pellets Made from Various Biomass Materials

various biomass materials of pellet processing

| Biomass Material | High Calorific Value | Low Calorific Value | Biomass Material | High Calorific Value | Low Calorific Value |

|---|---|---|---|---|---|

| Corn Stalk |

16.90MJ/kg (4039 CAL/kg) |

15.54MJ/kg (3714 CAL/kg) |

Sorghum Straw |

16.37MJ/kg (3,912 CAL/kg) |

15.07MJ/kg (3,601 CAL/kg) |

| Cotton Straw |

17.37mJ /kg (4,151 CAL/kg) |

15.99MJ/kg (3,821 CAL/kg) |

Soybean Straw |

17.59MJ/kg (4204 CAL/kg) |

16.15MJ/kg (3859 CAL/kg) |

| Rice Husk |

15.67mJ /kg (3745 CAL/kg) |

14.36mJ /kg (3432 CAL/kg) |

Cow Dung |

12.84MJ/kg (3068 CA/kg) |

11.62MJ/kg (2777 CAL/kg) |

| Pine Wood |

18.37MJ/kg (4,390 CAL/kg) |

17.07MJ/kg (4,079 CAL/kg) |

Peanut Shell |

16.73MJ/kg (3,999 CAL/kg) |

14.89MJ/kg (3,560 CAL/kg) |

If you are interested in starting biomass pellet manufacturing business, here, we can provided TURNKEY PROJECT that saves your time and money without compromising the quality of final produced pellets! Welcome to leave your contact information and processing requirements directly below, we will contact you in time!