Feed Mixing Process: Buying Animal Feed Mixer Machine for Your Plant

The feed mixing process is an indispensable key to the animal feed production process. In modern farming, precise feed mixing is not only an intertwining of animal processing technology and animal processing machines, but also a cornerstone for ensuring healthy animal feeding and efficient feed production lines. Whether you are new to farming or a seasoned expert, this article will present you with the best mixing machines and mixing processes for animal feed mills, designed to help you succeed in your animal feed processing plant.

Animal Feed Mixer Machinery and Mixing Technology

Key Standards for Mixing Process in a Successful Animal Feed Plant

- Mixing time should be maintained at 15 to 20 minutes per batch in animal feed mill production.

- The speed of animal feed mixer machine should be maintained at 50 to 100 rpm.

- The homogeneity of the mixed feed should be more than 95%

- The difference between different mixing batches should be controlled within ±1% in aniaml feed plant production.

- Large particles of animal feed should not exceed 5% after mixing.

Two Main Blending Methods: Batch Mixing Process vs. Continuous Mixing Process

Mixing process refers to the method and process of mixing the raw materials of each component of the feed formula into an animal feed mixing machine for uniform mixing and processing after weighing and batching. According to the continuity of the mixing process, the animal feed mill mixing process can be divided into batch mixing process and continuous mixing process.

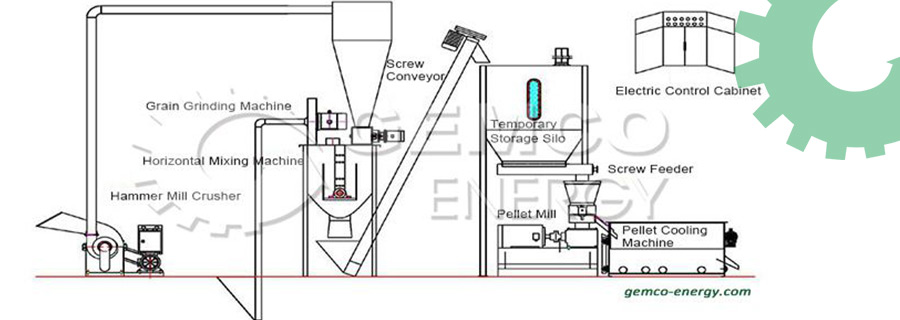

GEMCO's Complete Animal Feed Pellet Production Line Schematic Diagram

Animal Feed batch mixing process

Definition of Batch Mixing Process: The batch mixing process is to combine various mixing components together according to the proportion of the animal feed formula, and feed them into the batch mixer machine that works periodically to mix them in batches. Mixing a cycle, that is, the production of a batch of mixed feed, is the batch mixing process. The three working processes of feeding, mixing and discharging in a batch mixing system cannot be carried out at the same time. The three mixing processes constitute a complete mixing cycle of the animal feed processing line.

- Advantages of Batch Mixing Process: This feed mixing method is more convenient to replace the formula, the mixing quality is generally good and easy to control, and each batch is less mixed with each other.

- Disadvantages of Batch Mixing Process: The batch mixing process of weighing and feeding equipment opening and closing operations are more frequent, so most animal feed mills need to use automatic program control.

- Characteristics of Application Scenarios: At present, feed mill factory generally uses batch mixing techniques, especially for small animal feed mills.

Animal Feed Continuous mixing process

Definition of Continuous Mixing Process: The continuous mixing process is a variety of feed components at the same time, respectively, continuous measurement, and proportional with a stream containing a variety of components, when this stream of material into the continuous mixer machine. It is continuously mixed into a uniform stream.

- Advantages of Continuous Mixing Process: Continuous mixing method can be carried out continuously, working sections are easy to connect and simple to operate.

- Disadvantages of Continuous Mixing Process: When changing the feed formula, the flow rate adjustment is more troublesome; in the continuous conveying and continuous mixing equipment, the feed material residue is more, so the intermixing problem between the two batches of feed is more serious.

- Characteristics of Application Scenarios: The continuous mixing technique is suitable for large feed production plants because of its high efficiency. However, the feed production line should not change the feed formula too frequently because continuous mixing devices are not easy to clean.

Differences between Batch and Continuous Process

| Feature | Batch Mixing | Continuous Mixing |

|---|---|---|

| Operation Method | Batch processing | Continuous process |

| Mixing Machine | Batch Mixing Machine | Continuous Mixing Machine |

| Time Efficiency | Relatively slow | More efficient |

| Control Precision | Usually high | Depends on equipment |

| Equipment Complexity | Simple operation | More complex |

| Applicability | Small-batch, periodic | Large-scale, continuous |

| Mixing Quality | Generally good | Some uneven mixing |

| Cleaning/Maintenance | Relatively easy | May require frequent |

| Energy Consumption | Stop after each batch | Continuous operation |

If you have questions about batch mixing processes and continuous mixing processes for animal feed, or if you are considering buying feed mixing machines and complete animal feed production lines, please contact us directly! Our team offers you a wide range of efficient and reliable animal feed production solutions to meet your needs in the animal feed making process. (Read more about Technology and Equipment of Animal Feed Manufacturing Process>>)

Advanced Animal Feed Mixer Machine: Comprehensive Blending Solutions

In the above article, we have discussed two types of mixing processes used in animal feed processing plants. When it comes to mixing machines in animal feed plants, feed mixing equipment can still be categorized under two main categories: feed batch mixer machine and feed continuous mixer machine. Below is the introduction of animal feed mill mixer machines.

Batch Mixing Equipment Optimizing Feed Quality: Precision Blending

Batch Mixing Machines for Sale: Ribbon Mixer & Paddle Mixer & Rotating Mixer

Batch mixing machine is a kind of equipment that mixes various raw materials together according to a certain proportion. It includes horizontal ribbon mixing machines, vertical mixing machines, double cone rotary mixing machines and so on.

- Horizontal Ribbon Mixer: Horizontal ribbon feed mixer blends different types of feed ingredients through the rotation of ribbon blades, suitable for small feed plants.

- Vertical Mixer: Vertical feed mixer (vertical paddle mixer) mixes feed ingredients through the upward and downward rotation of blades, providing a good mixing effect, suitable for medium feed production plants.

- Double-Cone Rotary Mixer: Double cone rotating mixer mixes feed ingredients through the rotation of double cones, ensuring uniform mixing, suitable for large feed plants.

Continuous Mixing Equipment Speeding Up Processing: Efficient Production

Continuous mixing machine is a kind of equipment that can continuously mix raw materials, mainly including Horizontal Screw Continuous Mixing machines (Horizontal Spiral Continuous Mixer), Liquid Addition Mixing machines, Turbulent Mixing machines and so on.

- Screw Continuous Mixer: This horizontal feed mixer mixes feed ingredients continuously through the screw motion, suitable for large feed production plants.

- Liquid Addition Mixer: Liquid addition mixer mixes feed ingredients by adding liquid mixers, providing a good mixing effect, suitable for feed processing plants requiring liquid addition.

- Turbulent Mixer: Turbine mixer mixes feed ingredients through high-speed rotation, providing an excellent mixing effect, suitable for animal feed manufacturing lines with high requirements.

GEMCO: Your Trusted Animal Feed Machinery Partner

GEMCO's Animal Mixer Machines for Sale at Factory Price

If you are looking for feed mixer manufacturers, I hope you will consider us. GEMCO, as an animal feed machines supplier with nearly 30 years of experience, can provide flexible feed making machine configuration options to meet the needs of customers of different sizes and requirements. Our team will work with you to customize the best feed processing solution for your specific needs, ensuring a smooth and efficient production process.

When you choose our feed mixing equipment and production lines, you will benefit from advanced technology, reliable performance and full-service support. We are committed to providing our customers with excellent solutions to help you achieve greater success in the animal feed industry. Contact us now! We look forward to working with you to create a better future.