How to Start a Poultry Feed Business Successfully?

The poultry feed industry is a dynamic and promising sector that is experiencing unprecedented growth opportunities with the increasing demand for high quality and nutritious food and the expansion of poultry farming feeding. Growing demand for poultry feed products, innovations in feed processing technology, increased demand for healthy feeds and supportive national policies all provide growth opportunities for investors in the poultry feed making business.

How Much Does a Poultry Feed Business Cost?

Poultry Feed Business Startup Costs: Plant Investment Guide

Establishing a poultry feed business requires a comprehensive consideration of costs in various aspects, including raw material procurement, production equipment, plant rentals, staff wages, energy consumption and marketing. Among them, the poultry feed machine cost is a key factor as it directly affects the poultry feed quality and productivity. As a poultry feed machine supplier, ABC Machinery has an in-depth understanding of the cost of poultry feed making machines required for a poultry feed processing business and can provide you with a useful reference.

Small Poultry Feed Mill Costs and Prices

A small feed mill plant or small feed production line usually consists of a crusher, mixer, pelletizer, cooler and packaging machine. The poultry feed production machine cost of small feed processing lines are inexpensive, compact in design and easy to operate, making them ideal for rural areas, small farms, small breeding farms, and small feed processing plants. The small poultry feed production line has a high degree of automation and an easy-to-handle design, so even adults without professional training can use it skillfully. A couple of people can easily operate a mini poultry feed mill.

Mini Poultry Feed Machine Line for Home

Small Poultry Feed Pellet Processing Line

ABC Machinery's small poultry feed processing line is made of high quality materials and advanced technology, which not only ensures that the feed produced meets the standard, but also can be customized according to different needs, providing small feed mill investors with the most suitable poultry feed production solutions for their needs. Meanwhile, our professional team provides perfect after-sales service (including online and offline support) to ensure every customer's smoothness and satisfaction in the feed production process through timely technical support and maintenance. We are committed to providing high-quality and low-priced poultry feed processing machines for small businesses, aiming to help every investor who wants to start a small poultry feed business to maximize the economic benefits. If you are interested in our feed processing equipment or want to get the latest quotation, click the button below to inquire directly!

Large Poultry Feed Plant Costs and Prices

Large poultry feed mills occupy a pivotal position in the modern poultry farming industry, with many significant advantages:

- High Production Efficiency in Large Feed Mills

Large poultry feed mill plants are usually equipped with advanced poultry feed processing equipment and automated poultry production lines. These feed production equipments and production lines can greatly improve the production efficiency of the feed production plants and can meet the feed demand of large-scale farms and poultry feed wholesalers.

- Consistent Quality of Produced Products

Through strict quality control and standardized poultry feed production process, large-scale feed processing mills are able to produce high-quality poultry feed with uniform quality and balanced nutrition. Therefore, these poultry feed factories have stronger competitiveness in the poultry feed processing market.

- Large-scale Feed Plants with Cost Control Advantages

Scaled production helps to reduce the unit production cost of poultry feed factories. Optimize resource allocation and improve economic efficiency.

- Large-scale Feed Manufacturing Plants with Advanced Feed Processing Technologies

Large-scale poultry food plants usually use the latest feed manufacturing technology and equipment, and are able to carry out accurate poultry formula allocation to meet the nutritional needs of poultry at different stages.

Complete Poultry Feed Pellet Production Line for Sale

Turnkey Poultry Feed Processing for Sale

Modern Automatic Poultry Feed Mill

ABC Machinery offers customized poultry feed mill project services:

- Geographical Customization: Provide professional customized feed processing equipment solutions according to the special needs and environmental conditions of different geographical regions.

- Process Customization: According to the customer's feed processing process requirements, customize the workflow and parameters of the equipment to ensure the best processing results.

- Scale Customization: According to the customer's feed production scale and capacity requirements, customize the size and configuration of the feed production equipment, including power, size, material, etc., to achieve accurate feed production planning.

- Special Requirements: Provide personalized technical solutions for customers' special requirements, such as special material adaptation, special shape product processing, etc.

Choose the Right Poultry Feed Production Process to Make Your Business Plan Profitable

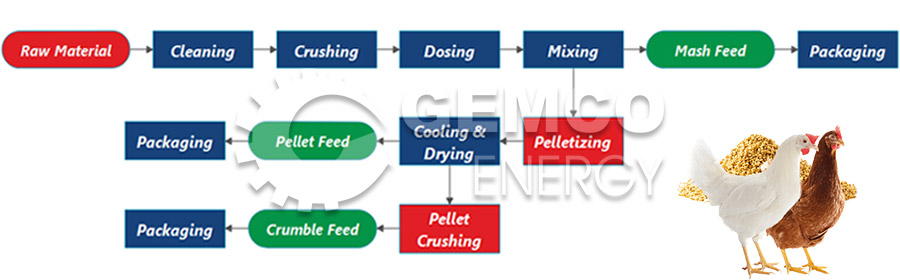

Usually, the feed processed in poultry feed making plants can be categorized into mash feed, pellet feed, crumble feed according to the form. These three kinds of feeds have their corresponding feed processing technology, and at the same time, these three kinds of technology have similarities.

Poultry Feed Manufacturing Process Flow Chart

For poultry mash feed, the raw materials are crushed and mixed directly into powder, which is suitable for some specific poultry feeding needs. Poultry pellet feed, on the other hand, involves pelletizing and cooling, where the mixed ingredients are pressed or extruded into pellets, a form that is easy to store and eat. For poultry crumble feed, the pellets are broken down again to suit the feeding habits or growth stages of the young poultry.

Regardless of the poultry feed processing process, it is necessary to comprehensively consider the composition of raw materials, animal demand and production efficiency and other factors, to choose the most suitable production process, in order to produce high-quality poultry feed. (Know more about Animal Feed Processing Process and Machines>>)

A Profitable Poultry Feed Business Plan: What You Must Consider

A profitable poultry feed business plan should consider:| Item | Content |

|---|---|

| Overview | Company name, business type, target market, competitive advantages |

| Market Analysis | Industry overview, target customer groups, market demand, competitive analysis |

| Products and Services | Product description, technical specifications, pricing strategy |

| Sales and Marketing | Sales channels, publicity and promotion, sales expectations |

| Operation Plan | Production process, supply chain management, human resources |

| Financial Planning | Expense budget, revenue forecast, profit expectation, fund raising |

| Risk Management | Risk identification, risk response strategy |

| Capital Requirements | Start-up capital, working capital, source of funds |