Strategic Wood Pellet Plant Design: Enhancing Workflow and Output Quality

Setting up a wood pellet plant is definitely a compelling business investment opportunity nowadays. The growing demand for renewable energy and the increasing focus on reducing carbon emissions create a favorable market for wood pellets business. Investing in a complete wood pellet plant allows for the production of a sustainable energy source while capitalizing on a lucrative market. Wood pellets offer a reliable and cost-effective alternative to fossil fuels, attracting both residential and commercial customers. Moreover, with the right design and efficient operation, a wood pellet plant can yield consistent profitability over the long term. By leveraging sustainable practices and meeting renewable energy targets, setting up wood pellet plant aligns with the global shift toward a greener future, positioning wood pelletizing businesses for financial success while contributing to environmental sustainability. (Read more: Biomass Pellet Project Cost >>)

Get Custom Layout Design Plant for Wood Pelletizing Business

Logical Layout Designs to Setup a Commercial Wood Pellet Plant

GEMCO stands out as an ideal partner for obtaining a cost-effective design for wood pellet production factory due to its unmatched expertise and industry reputation. With years of experience in the field, GEMCO has honed its capabilities in designing and installing complete biomass wood pellet plants. (Related post: Commercial Wood Pellet Equipment for Pellet Plant Setup >>)

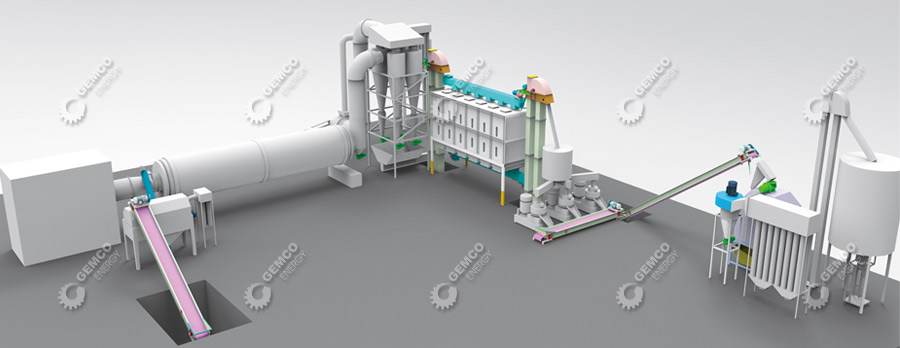

Commercial Wood Pellet Plant Design - Equipment Layout

Our teams of experts understands the intricacies of the wood pellet industry and can deliver customized solutions to specific needs, ensuring optimal efficiency and productivity while keeping costs in check. our commitment to cost efficiency is evident in their competitive pricing, enabling clients to achieve their production goals while maximizing their investment. Moreover, our integrated approach, encompassing equipment manufacturing, layout optimization, and continuous support throughout the project, guarantees a seamless and successful implementation. Our dedication to quality, reliability, and excellent after-sales service further solidifies our position as the go-to choice for efficient wood pellet plant design.

Whole Design of a Commercial Wood Pellet Plant Built by GEMCO

Why Should Choose a Reliable Supplier to Design Your Wood Pellet Plant?

Before setting up a wood pellet plant, a scientific design for factory and biomass pellet machine layout can ensure efficient, safe and sustainable wood pellets production and can maximize productivity, pellets quality, and profitability while minimizing risks and environmental impact.

- Efficient Resource Utilization: A scientific design and logic equipment layout of a wood pellet plant ensures optimal utilization of resources, including raw materials, energy, and manpower. It helps minimize waste and maximize production efficiency, leading to cost savings and increased profitability.

- Pelletizing Process Optimization: A well-designed plant layout allows for smooth and efficient material flow, minimizing bottlenecks and reducing downtime. It optimizes the sequence of operations, equipment placement, and workflow, resulting in improved productivity and overall wood pelletizing process optimization.

- Quality and Consistency: A scientific design ensures consistent product quality by considering factors such as raw material preparation, pelletization process parameters, and quality control measures. It helps achieve uniform pellet size, density, and moisture content, meeting customer specifications and enhancing market competitiveness.

- Safety and Risk Mitigation: A scientific design incorporates safety considerations, minimizing the risk of accidents, injuries, and equipment damage. It includes proper spacing, clear pathways, emergency exits, and safety protocols, creating a safe working environment for employees and reducing potential liabilities.

- Regulatory Compliance: Designing a plant with regulatory requirements in mind helps ensure compliance with local, national, and environmental regulations. It minimizes the risk of non-compliance penalties, project delays, or operational shutdowns.

- Scalability and Future Expansion: A scientific design takes into account future growth and expansion possibilities. It allows for scalability and easy integration of additional equipment, processes, or capacity upgrades without major disruptions to the existing plant layout.

- Sustainability and Environmental Considerations: Designing a wood pellet plant with environmental considerations promotes sustainable practices. It allows for the implementation of technologies and measures to minimize emissions, control dust, and utilize waste materials efficiently. A well-designed plant helps reduce the ecological footprint and supports the transition to a low-carbon economy.

- Cost-effectiveness: A scientific design helps optimize capital and operational costs. It allows for proper equipment sizing, efficient material handling systems, and automation, leading to reduced energy consumption, lower maintenance costs, and improved overall cost-effectiveness.