Wood Pellet Press Machine Making Hardwood and Softwood Pellets

Wood pellet press machine is a key technology widely used to process different types of wood raw materials into high quality wood fuel pellets. Through mechanical and thermal forces, the raw material is well compressed and pelletized to make efficient biomass fuel pellets and sustainable energy resources. This process not only improves the efficiency of the utilization of wood resources, but also has a positive impact on the environment and promotes the goal of sustainable development. Now, let us learn more about softwood wood pellets and hardwood pellets with biomass pellet press machines in this article. (Related to Common Raw Materials>>)

Hardwood Pellets and Softwood Pellets

Comparison of Hardwood Pellets and Softwood Pellets

Softwood pellet fuel and hardwood pellet fuel are two common biomass fuels that differ significantly in terms of energy production and environmental impact. So, wood pellet plant manufacturers should consider various factors when manufacturing wood pellets with the wood pellet press machine.

Essential Characteristics of Softwood Pellets

- Raw material: Softwood pellet fuel is usually made from the trunks and branches of softwood species such as fir and pine.

- Calorific value and combustion efficiency: Softwood pellet fuel usually has a low calorific value but high combustion efficiency. Softwood pellets are cleaner, because they produce less ash when burned.

- Sustainability: Softwood pellet fuels have a low environmental impact due to the fast-growing nature of softwood species and their harvesting.

- Price and supply: Cork pellet fuel usually has a low price and a relatively stable supply due to the more common species of softwood trees.

- Applications: Due to its high combustion efficiency and low emissions, softwood pellet fuel is commonly used for home heating and industrial heating.

Essential Characteristics of Softwood Pellets

- Raw material: Hardwood pellet fuel is mainly made from the wood of hardwood species, such as oak and maple.

- Calorific value and combustion efficiency: Hardwood pellet fuels usually have a higher calorific value, but the combustion process produces more ash. This may require more frequent cleaning and maintenance.

- Sustainability: Hardwood species require longer growth cycles, so their harvesting requires more time and resources, and sustainability is challenged.

- Price and Availability: Hardwood pellet fuels are typically more expensive and availability can be affected by seasonal and regional fluctuations.

- Applications: The high calorific value of hardwood pellet fuels makes them excellent for industrial processes that require high heat output, such as manufacturing and energy production.

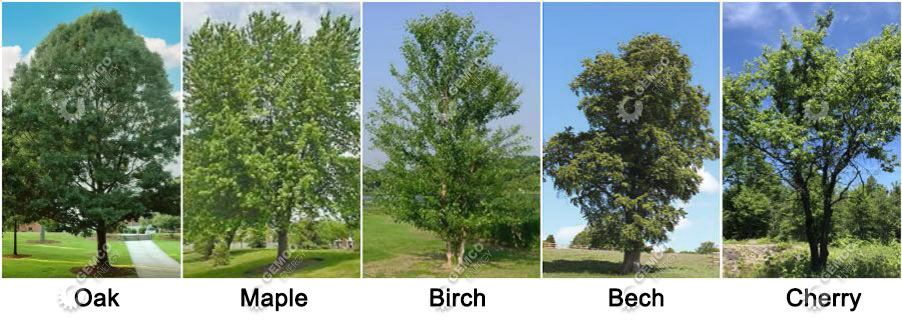

Raw Materials for Softwood and Hardwood Pellets with Wood Pellet Press Machines

Hardwood trees and softwood trees are the raw materials for hardwood pellets and softwood pellets with wood pellet press machine respectively. These two types of raw materials have their own unique properties and advantages. Next, we will take a brief look at some common hardwood and softwood trees.

Softwood Raw Materials for Wood Pellet Production machine in Wood Pellet Making Line

Comparatively speaking, softwood pellets have a lower cost and lower calorific value. It is about 10,000 -12,000 MBTU per ton, with a higher ash content of about 0.5% - 3%. This means that more ash is produced when burned and may require more frequent cleanup.

- Pine (Pinus spp.):

Pine has high density and calorific value, moderate burning rate, low raw material cost and easy to obtain. It is mainly distributed in the United States, Canada, and Mexico in North America. There are also many pine species in Europe, including the common Norway spruce and European larch. Pine is also widely distributed in Asia, including Siberia, China, Japan, India and elsewhere.

- Fir (Fagus spp.):

Fir wood pellets have a high density and high calorific value and burn efficiently. However, due to its limited distribution, the raw material cost is high. Fir is widely distributed in North America, including Canada, the United States, and Alaska. Fir is also common in Asia, especially in Siberia. Siberian spruce is one of the most famous fir species in Siberia. In addition, fir is also found in the Alpine region of Europe.

- Cedar (Cedrus spp.):

Cedar wood pellets have medium density and high calorific value, good combustion efficiency, moderate cost and easy to obtain. It is widely distributed, including coastal areas of North America, Europe, and Asia.

- Spruce (Picea spp.):

Spruce wood pellets have high density and high calorific value, high combustion efficiency, but due to the limited distribution, high cost. Mainly distributed in the northern hemisphere in the frigid and temperate regions and high mountain plateau areas. Such as Canada, the United States and Alaska in North America, Norway in Europe, Siberia in Asia, and North China.

- Aspen (Populus spp.):

Aspen wood pellets have low density, moderate calorific value, fast burning speed, low cost, and easy availability. It is mainly distributed in North America and Europe. In addition, aspen is widely planted in industrial forests, which reduces the harm to natural forests while keeping costs low.

Hardwood Raw Materials for Wood Pellet Mill in Wood Pellet Production Line

Hardwood pellets cost more but also have a higher calorific value of 16,000 - 16,600 MBTU per ton. In addition, hardwood pellets typically have an lower ash content of 0.5% to 1.5%.

- Oak (Quercus spp.):

Oak wood pellets have high density, high calorific value, and excellent combustion, but relatively high cost. It grows mainly in the temperate and subtropical regions of the northern hemisphere. They can be found in various regions of North America, Europe, Asia, and Africa.

- Maple (Acer spp.):

Maple wood pellets medium density, moderate calorific value, moderate burning speed, moderate cost, easy to obtain. Maple is typically found in temperate and boreal regions of the Northern Hemisphere, including North America, Europe, Asia, and North Africa. North America is the main distribution area for maple, especially Canada and the United States.

- Birch (Betula spp.):

Birch wood pellets have medium density, moderate calorific value, good burning efficiency, and moderate cost. Birch wood is widely distributed, usually grown in the northern hemisphere in the cold and temperate regions such as North America, Europe, Asia and North Africa and other regions.

- Beech (Fagus spp.):

Beech wood pellets have medium density, moderate calorific value, good combustion efficiency and moderate cost. Beech is widely distributed in North America, Europe and Asia and other regions. They grow in temperate and subtropical mountains, plains, and forested areas in the northern hemisphere.

- Cherry (genus Plum):

Cherry wood pellets have low density, moderate calorific value, fast burning speed and low cost, but relatively limited distribution Cherry trees are widely distributed in temperate regions of the Northern Hemisphere, including Europe, Asia, and North America.

Characterization of Tree Species Used in Wood Pellet Plant

| Classification | Species | Moisture Content | Ash Content | Density (kg/m³) | Calorific value (MBTU/ton) |

|---|---|---|---|---|---|

| Softwood | Pine | 30-60% | 0.3-1.0% | 400-600 | 16-19 |

| Fir | 30-60% | 0.3-1.0% | 450-550 | 16-19 | |

| Cedar | 30-60% | 0.3-0.7% | 400-500 | 16-18 | |

| Spruce | 30-60% | 0.3-0.8% | 350-550 | 16-19 | |

| Poplar | 30-60% | 0.3-0.8% | 450-600 | 15-17 | |

| Hardwoods | Oak | 30-60% | 0.3-1.0% | 600-800 | 19-24 |

| Maple | 30-60% | 0.3-0.8% | 500-700 | 18-21 | |

| Birch | 30-60% | 0.3-0.8% | 400-600 | 17-20 | |

| Beech | 30-60% | 0.3-0.8% | 450-650 | 20-25 | |

| Cherry | 30-60% | 0.3-0.8% | 500-700 | 18-22 |

These are just some of the common tree species that can be made into pellets by wood pellet manufacturing mills. In fact, wood from many species can be used as a feedstock for wood fuel pellets. And in commercial pellet mills or when making homemade wood pellets, softwoods and hardwoods are often mixed in a certain proportion to pursue better combustion effects. Usually, what is important to note for the novice plant builder is that the specific choice of feedstock will be influenced by the target production volume of the biomass pellet plant, the region and the resources available. (Learn more about Raw Material of Biomass Pellets>>)

Contact us for free! You can learn more information, and you can also mail the raw material to our wood pellet factory for trial processing.

Selecting Machine for Processing Wood Pellets in Biomass Pellet Production Plant

For raw materials to be turned into pellets, they need to go through a pretreatment stage and a pellet molding stage. Different equipment is used in different stages. Therefore, newcomers need to understand the different equipment and make the best choice. (Related to Equipment Selection Guide>>)

Raw Material Processing Machinery at the Pretreatment Stage

When producing wood pellets, various machines are used at the feedstock preparation stage to convert the raw wood into a suitable form for pellet production. Below are a few key pieces of equipment that play an important role in the wood pellet feedstock preparation process.

Auxiliary Equipments in Wood Pellet Processing Line

- Wood Chipper

The wood chipper machine is the first step in wood pellet production. It cuts large pieces of virgin wood into smaller chips, flakes, or chunks. These smaller pieces are usually sized to be less than 3 mm thick and 10 - 30 mm long, making subsequent processing easier.

- Hammer Machine

The hammer machine further crushes the wood chips obtained into finer particles according to specific needs. Generally, the raw materials with the diameter around 30mm can be crushed into small pieces with the 2 - 5mm diameter.

- Dryer

The moisture content of the raw material directly affects the performance of wood pellet molding and combustion. Drying equipment is used to evaporate the water in the feedstock and reduce its moisture content to a suitable level (ideal moisture content: 10%-20%) to ensure the preparation of stable wood pellets.

At the raw material pre-processing stage, the softwood may need to go through fewer preprocessing steps because of softer properties. Softwoods usually do not require the same rough crushing or debarking as hardwoods. Conversely, hardwoods are typically harder and may need to undergo more pretreatment processes such as crushing, peeling and drying to make them easier to process in a pelletizer machine.

Wood Pellet Maker machine in the Pellet Forming Stage

- Flat Die Pellet Mill

Flat die pellet machine usually uses a flat die to make pellets from raw materials by compression and extrusion. This pellet press is low cost and easy to operate, making it ideal for start-ups with small scale production or customers with budget constraints. It is also a good choice for a home wood pellet machine.

- Ring Die Pellet Mill

Ring Die Pelletizers use a circular die where the raw material is compressed and made into pellets as it rotates inside the die. Ring die pellet maker is more costly but is preferred by customers looking for high quality and large scale production.

In terms of wood pellet processing machine selection, biomass wood pellet machines need to be aware that lighter wood pellet manufacturing machines can usually be used to process softwood pellets because softwoods are easy to process and compress into pellets. In addition, softwood pellets require longer compression and larger hole molds because they are usually fluffier. During this process, the wood pellet production line also needs to control lower temperatures to prevent overheating and pellet distortion due to the increased temperature caused by the long compression time. On the contrary, as tougher materials, hardwoods are often used by heavier wood pellet press machines with higher temperatures and pressures.

GEMCO: Your Best Partner for Wood Pellet Production

Please feel free to contact us, if you have more questions or need detailed information about softwood and hardwood pellet materials or wood pellet press machines. GEMCO, as wood pellet making equipment suppliers with nearly 30 years of experience, provides high-quality pelletizing solutions to our customers. Our team of professionals is dedicated to supporting you and meeting your needs. If there is anything you need, please contact us for free support!