PTO Pellet Mill

GEMCO is the first pellet mill machine manufacturer to USES PTO power in China. PTO pellet mill can be directly connected to the tractor when it is inconvenient to use electricity outdoors. It is movable, easy to install and operate, which make it a good choice for outdoor biomass wood pellet processing. (Read more: Biomass Wood Pellet Machine >>)

Biomass Pellet Making By PTO Pellet Mill

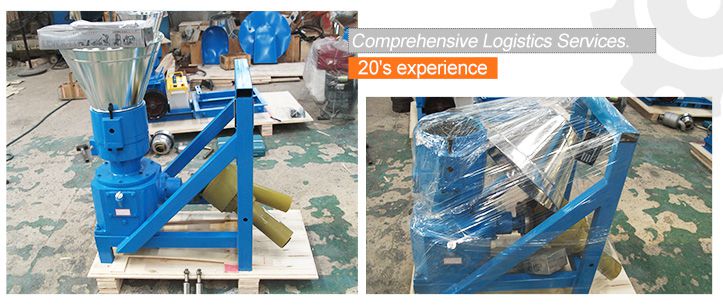

PTO Pellet Mill for Sales

PTO pellet mill is also a popular type of mini pellet mill for farm use. PTO is the abbreviation of Power Taken Off, which means PTO pellet mahcine should be connected with a tractor and driven by the tractor. It is especially suitable for who has already got a tractor. The power you choose for the pellet mill PTO should be in accordance with your tractor. (Related Post: Farm Pellet Mill >>)

Raw Materials PTO Pellet Mill Can Process

Since the PTO pellet mill is specially designed for people who has a tractor, it is able to process various agro or crop wastes like wheat straw, cotton stalk, corn stover, rice husk, peanut shell, and also wood sawdust, grass, leaves, etc.

Raw Materials for PTO Pellet Machine

The pellets made by pellet mill machine driven by PTO can be used for fuel, animal bedding or even animal feed. Please contact us to get detail technical information to make biomass pellets or animal feee pellets with PTO pellet machine. (Read more: poultry feed manufacturing plant cost >>)

Factory Price PTO Pellet Making Machine

Technical Data of PTO Pellet Mill

| Model | Power | Capacity | Weight (NW/GW) | Packing Size |

|---|---|---|---|---|

| ZLSP120P | ≥8 HP | 40-80 kg/h | 80/100 kg | 900*540*900mm |

| 90-180 lbs/h | 175/220 lbs | 35*21*35inch | ||

| ZLSP150P | ≥10 HP | 50-100 kg/h | 90/110 kg | 900*540*1020mm |

| 110-220lbs/h | 200/245 lbs | 35*21*40inch | ||

| ZLSP200P | ≥15HP | 80-120 kg/h | 130/150 kg | 1000*540*1020mm |

| 180-265lbs/h | 290/330 lbs | 39*21*40inch | ||

| ZLSP230P | ≥22HP | 120-200kg/h | 175/200 kg | 1000*540*1020mm |

| 245-440lbs/h | 385/440 lbs | 39*21*40inch | ||

| ZLSP260P | ≥33HP | 160-250kg/h | 235/260 kg | 1050*540*900mm |

| 350-550lbs/h | 518/580 lbs | 41*21*35inch | ||

| ZLSP300P | ≥41HP | 250-400kg/h | 305/330 kg | 1100*540*1000mm |

| 550-880lbs/h | 680/730 lbs | 43*21*39inch |

Please Note: GEMCO Pellet Mill also provide other types that can be driven by electrical engine, diesel engine, and gasoline. If there are any needs for other types of wood pellet mill machine, please contact us directly to get the product catalogue and price list!

Mini PTO Wood Pellet Mill Working Video

Buy High Quality PTO Pellet Mill for Making Biomass Wood Pellets: HOT Sale PTO pellet mill offered by PTO pellet mill manufacturer or supplier, guide on process of biomass wood pellet production and how to start PTO pellet mill business with limited cost in Tanzania, Egypt, Morocco, Ghana, South Korea, etc.

Advantages of PTO Wood Pellet Mill Machine

PTO Wood Pellet Mill for Sale

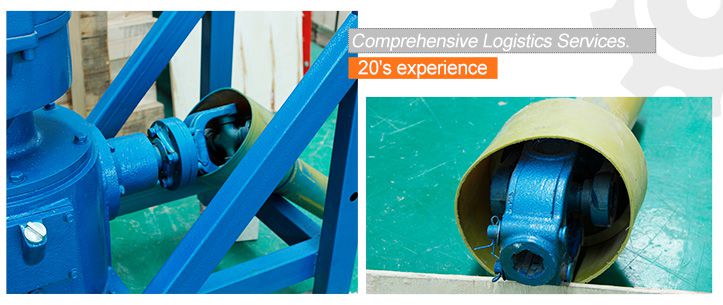

- Efficient and Energy-saving: Reasonable and scientific design allows stable and uniform pelletizing process

- High Quality Pellets: The pellets produced by PTO wood pellet mill has smooth surface, uniform posture and high hardness

- Easy to Use: Powered by mobile tractor, so pelletizing can be achieved anytime anywhere

- Long-term Service Life: The machine is made from high quality alloy steel to ensure wear-resistant and durable performance

- Flexible Pelletizing: Provided with various aperture die to meet different pellet making needs

Requirements for Biomass Pelletizing

Biomass pellet belongs to the biomass energy. Although many investors are interested in pellet production, most of them have no clear ideas the requirements of biomass pelletizing and also don’t know how to gain the profits by investing the biomass pellet plant.

Biomass Pelletizing

There are three general requirements for pelletizing: raw material, pellet size the humidity. As long as the three requirements can be met during the pelleting process, a good pellet fuel can be produced.

- Raw Materials Requirement

Raw materials for biomass pellets manufacturing generally are agricultural and forestry waste, such as straw, cotton stalk, sawdust, branches, straw, fruit shell, waste wood, etc. When starting the pelletizing business or setting up a biomass pellet plant, it is recommended to check which raw materials are available and can be timely supply. Once the wood pellet production line is running normally, shortage of the raw materials is likely to cause shutdown and bring huge loss.

- Pellet Size Requirement

The size of pellets affects the biomass pellet production process. The pellet size requires the raw material to be crushed into a size of about 5MM to 10MM by a crushing machine, which can only be used if it meets the standard.

- Humidity Requirement

The requirement for pelletizing also requires humidity, 8% to 12%, which can be done using a dryer, only when the standard humidity is met, when making granular fuel.