Types of Poultry Feed Pellets and Advanced Processing Methods

Explaining Different Types of Poultry Feed Pellets and Processing Techniques

There are many different types of feeds in poultry production. When you enter the field of poultry feed processing, you may encounter some troubles:

How to produce poultry feed at a low cost?

How to make poultry feed pellets? How to make chicken feed mash?

Is it better to make broiler chicken feed pellets or mash feed?

Which is better for chickens, pellets or crumbles? Which is the best type of chicken feed?

How to start your feed production for poultry? Is poultry feed production profitable?

Classifying Different Types of Poultry Feed by Nutrient Composition

Obviously, we cannot exhaustively discuss all kinds of poultry feeds in one article. Therefore, we can only pick some common types to cover. Firstly, let us understand how feed types for poultry are categorized according to their nutrient content.

- Poultry Complete Feed:

A complete feed is a comprehensive poultry feed that contains all the nutrients needed for poultry growth. It meets the nutritional needs of poultry at all stages of growth and can be fed directly without adding any ingredients.

- Poultry Complementary Feed:

Complementary feeds are poultry feeds made up of energy feeds, protein feeds and mineral feeds mixed in certain proportions. The cost of complementary feed is low, and the choice of feed ingredients is very flexible, can basically meet the nutritional needs of poultry, but its nutritional composition is not very comprehensive.

- Poultry Protein Supplement Feed:

Protein supplement feeds, also known as protein concentrate feeds, are designed to meet the high protein requirements of poultry. For example, protein supplements for chickens usually contain more than 30% protein, as well as higher levels of minerals and vitamins than required by feed standards. Therefore, protein supplement feed cannot be fed directly, but by adding energy feeds in certain proportions, they can be formulated into a complete nutritional complete feed.

- Poultry Additive Premix:

Additive premixed feed is a variety of nutrients and functional additives mixed in a certain proportion of poultry feed. These feeds are often using poultry raw materials such as cornmeal, soybean cake meal and flour as a carrier, in the poultry feed making process, according to the types and stages of poultry to form a semi-finished feed.

Classifying Poultry Feed Types Based on Shapes and Sizes

Poultry feed types can be categorized as feed mash/powder, feed pellet, feed crumble by form. This is the most common type of feed in the poultry feed market.

Poultry Mash Feed Vs. Poultry Pellet Feed Vs. Poultry Crumble Feed

Mash Feed for Poultry:

Mash feed is a type of powdered feed that is mixed in certain proportions and crushed to a relatively uniform particle size. Mash feed appears as a fine powder with a fineness of about 2.5 mm or more.

Advantages:

- Feed production equipment and process are relatively simple; less power consumption, low feed processing costs.

Disadvantages:

- Easy to cause animal's picky eating, resulting in waste. For example, feeding chickens wastes 6%~10%;

- Easy to waste and loss in the transport and storage process

Pellet Feed for Poultry:

Poultry feed pellets are presented in the form of regular granules, generally between 2~5 mm in size, and usually in the shape of a sphere or pellet.

Advantages:

- Reduce wastage and improve feed utilization.

- Avoid nutritional imbalances caused by picky eating.

- Good application effect, usually can gain 5 ~ 15% or more of weight of poultry.

Disadvantages:

- Not convenient for some small poultry to feed.

- The cost of making poultry feed pellets is higher than powder feed.

- Poultry feed pellet production machine causes some vitamins and enzymes to lose activity during heating and pressurization.

Crumble Feed for Poultry:

The currently recognized method of processing crumble feed to save the cost of poultry feed production lines is crushing the processed poultry feed pellet into 2-4 mm pieces. Chicks usually use crushed crumble feed. Crumble Feed is easy for poultry to eat and absorb while ensuring balanced nutrition. However, processing poultry feed pellets into crumble feed, which requires more production cost of poultry feed mills.

Chicken Feed Pellets VS. Chicken Feed Crumbles

| Features | Poultry Feed Pellet | Poultry Crumble Feed |

|---|---|---|

| Feed Particle Size | About 3-5 mm in diameter | About 3-5 mm in diameter |

| Nutritional Homogeneity | Uniform distribution | Uniform distribution, but slightly worse than pellet |

| Storage Stability | Relatively stable, not easily broken or deformed | Relatively stable, not easily broken or deformed |

| Cost of Poultry Feed | Usually cheaper than crumble feed | Usually cheaper than crumble feed |

| Application of Feed | Suitable for all types of poultry, e.g. chickens, ducks, turkeys, etc. | Suitable for all types of poultry, but more common in young and small poultry |

| Nutritional Retention | Relatively stable | Relatively stable |

| Digestion and Absorption | May take more time to digest | May take more time to digest |

If you are interested in different forms of poultry feed or have questions, you can consult us for free!

Insights into Poultry Feed Production Process: Making Various Fodder Types

When you start a poultry feed production business plan, you need to determine the process of feed production for and buy poultry feed processing machines for poultry feed production lines based on the manufacturing process. (Learn more about Animal Feed Production Process>>)

Poultry Mash Feed Processing Process

The mash/powdered feed making process usually consists of the following major steps: raw material preparation, crushing, mixing and dosing, addition of nutrients, drying and cooling, as well as packaging and storage. Through these steps, high-quality and nutrient-rich powdered feeds can be produced to meet the growth and development needs of poultry.

Poultry Feed Pellet Manufacturing Process

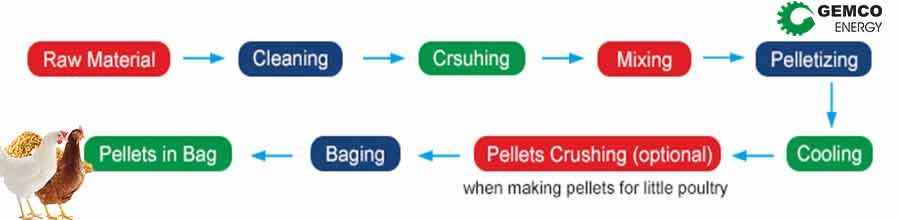

Poultry feed pellet processing technology is a process in which raw materials are crushed, mixed, pelletizing, and cooled to convert them into pellet feed.

Poultry Feed Manufacturing Process Flow Chart

Poultry Feed Processing Equipment in Production Line

Firstly, raw materials are pre-treated, including cleaning, screening and crushing, etc., so that the feedstuffs are attached to the subsequent feed manufacturing line processing requirements. Next, the various raw materials are mixed in accordance with a specific poultry feed making formula, and a feed mixer machine ensures that the various nutrients are evenly distributed. Subsequently, the mixed ingredients are pressed through a poultry feed pellet processing machine to form pellets. And then, poultry feed pellets are rapidly cooled in a cooling machine to solidify the pellets and maintain their shape. Finally, poultry pellet feeds are stored in a dry and ventilated warehouse.

Poultry Crumble Feed Processing Technology

Poultry crumble feed processing refers to the process of crushing the processed poultry pellet feed into smaller particles through the poultry feed crumbles machine. This process is usually used to adjust the poultry feed pellet size to meet the digestive requirements of various animal species or specific feeding conditions.

If you need more detailed information on the process, click the button below to get your own free poultry feed manufacturing process pdf.

Enhance Efficiency, Optimize Quality: Gemco's Poultry Feed Production Solutions

Complete Small Poultry Feed Pellets Line for Sale

Large Poultry Feed Pellets Mill Plant for Sale

Small Poultry Feed Processing Machine Uint for Home

Mobile Feed Machine Set for Sale

Whether you want to set up a poultry mash feed plant or poultry pellet feed plant, you can contact us below to get a free consultation. GEMCO, as an excellent poultry feed processing machine manufacturer, has a team of experienced and professional knowledge. We are committed to providing you with a wide range of state-of-the-art poultry feed production machines and technology to ensure that your poultry feed plant production is efficient, consistent and compliant. Contact us now for a free consultation and start your poultry feed processing journey!