Invest in a Sheep Manure Pellet Machine for Sustainable Fertilizer

Sheep manure is a rich organic resource, full of nitrogen, phosphorus, potassium, and other nutrients, making it an ideal raw material for organic fertilizer. With growing demand for sustainable agricultural practices, sheep manure pellets have become increasingly popular. This article will explore the working principles of sheep manure pellet-making machines, the benefits of using these machines, and why investing in such manure management equipment is a wise choice for fertilizer producers.

Sheep Manure Pellet Machines in Organic Fertilizer Plant

Sheep Manure Fertilizer Pellet Production Process and Equipment

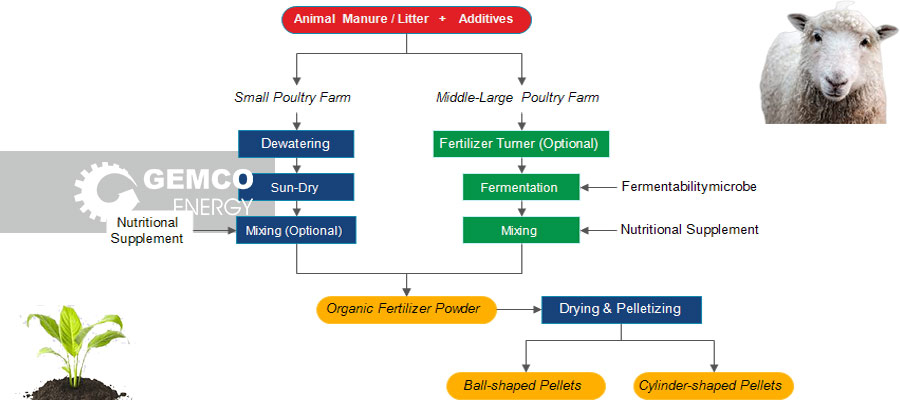

The process of turning sheep dung manure into granular fertilizer not only promotes waste utilization but also enhances crop yields. Below are the detailed processing steps, along with the key fertilizer pellet machine required at each stage.

Sheep Manure Fertilizer Manufacturing Process Flow Chart

1. Fermentation of Sheep Manure

Fresh sheep manure is rich in bacteria and parasite eggs and must undergo fermentation for sanitization. GEMCO offers fermentation tanks and pits, both of which are commonly used in the organic fertilizer industry. However, to improve fermentation efficiency and reduce environmental pollution, we recommend using manure dewatering equipment.

- Fermentation Tank Equipment:

The fermentation tank is a fully enclosed, high-efficiency device that controls temperature, humidity, and oxygen levels precisely through an intelligent system. It can complete compost sheep manure within 5-7 days, significantly shortening the traditional fermentation period and minimizing odor emissions and pollution.

Once the fermentation is complete, the processed sheep manure is transformed into a high-quality organic fertilizer base, ready for the next stage.

2. Crushing Process

After fermentation, sheep manure needs to be crushed to ensure the final pellets are of uniform fineness, facilitating better molding.

- Crushing Equipment:

We recommend a high-efficiency crusher that can break down sheep poop fertilizer into a fine powder of 0.5-1mm. The equipment is made from wear-resistant materials, ensuring long-lasting performance and low maintenance costs.

3. Mixing and Molding

The crushed sheep manure is then mixed with other additives (such as trace elements and minerals) to ensure comprehensive nutrition in the fertilizer pellets. The next step is the pellet molding process.

- Mixing Equipment:

A double-shaft horizontal mixer efficiently combines sheep manure with additives, ensuring a uniform nutrient distribution across each pellet.

- Pelletizing Equipment:

After mixing, the material is fed into a manure fertilizer pelletizer machine. Sheep manure fertilizer making machine can be a flat die pellet mill or ring die pellet mill, depending on production requirements. The sheep manure fertilizer pellet making machine compresses the mixture into pellets with diameters ranging from 3-6 mm, suitable for various crops and fertilization methods. Equipped with an automatic lubrication system, this sheep manure pellet machine can achieve up to 90% pressing efficiency.

4. Cooling and Drying

The newly formed pellets contain high moisture levels, requiring cooling and drying to ensure they remain mold-free during storage and transport.

- Cooling and Drying System:

The cooling and drying system can reduce the moisture content in pellets from 10-15% to below 8%. Our system is equipped with an automatic control feature, allowing for rapid cooling and uniform drying. This process shortens the drying time by 20-30%, enhancing production efficiency.

5. Screening and Packaging

Dried pellets are screened to remove any that do not meet quality standards and are then packaged for transport and sale.

- Screening Equipment:

The fully automatic screening machine quickly sorts out sheep pellets fertilizer that meet the standards, ensuring that each bag of fertilizer is of uniform quality.

- Packaging Equipment:

The final product is packaged by a fully automatic packaging machine with a speed of 25-30 bags per minute, ensuring efficient output. The packaging machine supports automatic weighing, sealing, and labeling, making it convenient for later market distribution.

Factory Price Sheep Manure Fertilizer Machine in Production Plant for Sale

GEMCO’s fertilizer manufacturing equipment offers excellent cost-effectiveness, long service life, and ease of operation. If you are looking for organic fertilizer pellet machine tailored to your organic fertilizer production needs, we can customize a sheep manure fertilizer production business solution that maximizes your sheep manure fertilizer plant production efficiency.

Benefits of Pelletised Sheep Manure Fertilizer

Granulated sheep manure for vegetable gardens is not only highly beneficial for agriculture but also supports ecological sustainability. Below are the advantages of using organic fertilizer pellets made from sheep manure:

- High Organic Content: Sheep manure typically contains 40-60% organic matter, much higher than other animal manures, significantly improving soil organic levels and structure.

- Rich Nutrients: Sheep dung manure is rich in 1.2-1.4% nitrogen, 0.5-0.7% phosphorus, and 0.8-1.0% potassium, providing comprehensive nutrients for crops, boosting crop yield, and supporting soil microbial activity.

- Slow-Release Characteristics: Granulated fertilizers gradually release nutrients, minimizing waste and reducing costs. Studies show that the slow-release effect of pellets is 30-40% better than bulk fertilizers.

- Improved Soil Moisture Retention: Organic sheep manure pellets enhance soil’s water retention and aeration, especially beneficial for arid or barren soils. Research indicates that sheep manure for garden granules can increase soil water-holding capacity by 20-30%.

Sheep Manure Pellets as Biomass Fuel

In addition to serving as fertilizer, sheep manure pellets can also be used as biomass fuel. This eco-friendly fuel boasts good combustion performance and can partly replace traditional fuels, reducing costs. The main features of organic sheep manure as fuel are as follows:

- High Calorific Value: After processing, sheep manure pellets can achieve a calorific value of 3000-3500 kcal/kg, close to that of wood pellets. This makes them an ideal alternative to coal in small- and medium-sized biomass boilers.

- Low Emissions: Burning sheep poo fertilizer emits 60-70% less CO2 compared to coal, with significantly lower sulfur and dust emissions, meeting environmental standards in many countries.

- Economic and Practical: The production cost of compost sheep manure pellets is relatively low, especially in areas with abundant agricultural waste. It’s estimated that producing one ton of sheep manure pellets costs around $80-120, while the market price is around $200-250 per ton, offering significant economic benefits.

Sheep manure pellets are widely used in agricultural communities, rural heating, and biomass power generation projects. If you’re interested in learning more about biomass fuel production equipment and its economic advantages, please contact us. Our expert team will provide you with detailed solutions and technical support.

Complete Biomass Pellet Production Line for Biofuel

Utilizing sheep manure pellet making machine either for fertilizer manufacturing or biomass fuel is ideal for boosting crop yields and promoting economic benefits. As a professional sheep manure pellet equipment supplier, GEMCO not only provides farmers and businesses with efficient sheep manure pellet equipment, but also offers comprehensive technical support throughout the process.

Choose GEMCO's sheep manure pellet plants for quality equipment, durable designs, and environmentally compliant processes that help customers effectively increase productivity and reduce operating costs. With nearly 30 years of industry experience, our team understands market needs and provides customized solutions.

If you have any questions about the performance or application of your sheep manure pellet mill, please feel free to contact us. Our professional team will provide you with comprehensive equipment consultation and customized services to help you maximize the use of your resources and achieve the desired return on investment.

- Chicken Manure Fertilizer Machine

- Cow Dung Fertilizer Production Machine

- Horse Manure Fertilizer Making Machine