How Wood Pellets Are Made to High Quality Standards

Wood fuel pellets are a solid fuel made from wood and wood product waste and are widely used in energy replacement and carbon neutral efforts. The quality of wood fuel pellets is critical to realizing their potential and true sustainability. How to manufacture wood pellets that meet quality assessment criteria is one of the concerns of every wood pellet plant manufacturer and pellet producer. Next, we will learn together about the general standards and certification systems for the production of wood pellets.

How Wood Pellet are Made to High Quality Standard?

Key Standards for Wood Pellet Production in Wood Pellet Making Plant

There are various wood pellet quality standards, but in general, all wood pellet manufacturing plants should follow general standards. Such as moisture content, density, size, and ash content of wood pellet products. Only when these minimum quality standards are met can wood pellet products be distributed in the market. These general generic standards help ensure the sustainability and market competitiveness of quality wood pellets. (Link to Wood Pelletizer Making High Quality Biofuel Pellets>>)

Making Best Quality Wood Pellets

- Moisture Levels in Wood Pellet Products

Best quality wood pellets typically have a moisture content of between 8% and 12%. Lower humidity provides a higher calorific value because it doesn't take too much energy to evaporate the water. However, it is important to note that too low a moisture content can cause wood pellet fuel to be friable and unfavorable for storage.

- Density of Wood Pellet Fuels

The density of wood fuel pellet products is usually required to be between 600 kg/m³ and 750 kg/m³. However, the exact density value of premium quality pellet may vary depending on the type of wood and treatment. Below are some density values for wood feedstocks. (Learn more about Raw Material Properties>>)

| Wood Fuel Type | Density (Kg/m³) | Energy Yield (MJ/Kg) | Combustion Characteristics |

|---|---|---|---|

| Birch | 600 - 700 | 19 - 21 | Rapid combustion, large flame, high heat, high calorific value |

| Oak | 700 -900 | 21 - 24 | Long-lasting combustion, stable flame, high calorific value |

| Pine | 350 - 700 | 15 - 18 | Fast burning, large flame, relatively low calorific value |

| Willow | 300 - 500 | 16 - 19 | Fast burning, large flame, good for ignition |

| Walnut | 550 - 700 | 21 - 24 | Long lasting burn, stable flame, high calorific value |

| Eucalyptus | 600 - 1000 | 17 - 19 | Fast burning, large flame, relatively low calorific value |

| Cherry | 600 - 700 | 18 - 20 | Long-lasting burn, stable flame, relatively high calorific value |

- Size and Dimensions of Pellets

The diameter size of the pellets is usually 6mm and 8mm, with a few wood pellets with diameters of 4mm and 10mm also available. The diameter of best rated wood pellets can be customized according to customer requirements. However, the length is generally required to be no more than 40mm. Because too long wood pellet fuel tends to cause clogging in the feeding system of the pelletizing machine. (Link to Flat Die Pellet Mill Design>>)

- Ash Content of Wood Fuel Pellets

Ash content influences the combustion performance and calorific value of wood pellets. Lower ash content usually means that wood pellets have a higher calorific value and produce less ash. Therefore, premium wood pellets with less ash content are more popular in the pellet fuel market. In general, the ash content of wood pellets is usually between 0.5% and 1.5%. Below are some common estimates of the ash content of wood pellets. (Learn more about Softwood and Hardwood Raw Material Properties>>)

| Raw Material | Hardwood Pellets | Softwood Pellets | Teak Pellets |

|---|---|---|---|

| Ash Content | 0.5%-1.0% | 0.7%-1.2% | 1.0%-1.5% |

The above mentioned general standards for wood pellets are usually the most basic requirements in the production of wood pellets. Excellent wood pellet press machines play a key role in making wood pellets of high quality standards. In addition, for many first time factory builders, finding experienced engineers can be effective in avoiding many production mistakes. If you want to learn more about wood pellet standards or wood pellet production line design and price, do not hesitate to ask us!

International Standards and Certification Systems for Wood Pellets

International standards and certification systems for wood pellets help consumers, suppliers, and manufacturers to recognize what the premium quality wood pellets are, and how wood pellets are made based on wood pellet quality standards. Next, there are international standards for premium quality pellet and related certification processes described.

International Wood Pellet Assessment Criteria

International Pellet Quality Certification System

- ENplus Certification

In the European pellet fuel market, the ENplus A1 certificate is highly prevalent. And the ENplus A1 wood pellet specification enjoys broad recognition across the global industrial wood pellet market. It is designed to ensure the quality and performance of the pellets.

- ISO Standards

The International Organization for Standardization (ISO) has published several wood pellet standards that are designed to ensure product quality, environmental sustainability, and compliance of the production process.

- FSC Certification

Forest Stewardship Council (FSC) certification emphasizes sustainable forestry management. If your wood pellet raw material comes from FSC-certified sustainable forest land, your product can be FSC-certified.

- DIN PLUS Certification

DIN PLUS certification is a German certification for high quality wood pellets. It emphasizes the selection of raw materials, quality control of the manufacturing process and consistency of the product.

- EPA Certification (USA)

The certification requirements of the U.S. Environmental Protection Agency (EPA) focus on environmental and emission standards, requiring that biomass pellet products produce fewer pollutants when burned.

- PEFC Certification

The Program for Sustainable Forestry Management (PEFC) requires suppliers to ensure that their wood pellet raw materials are sourced from sustainably managed forest land and meet requirements such as transparency and traceability in the supply chain.

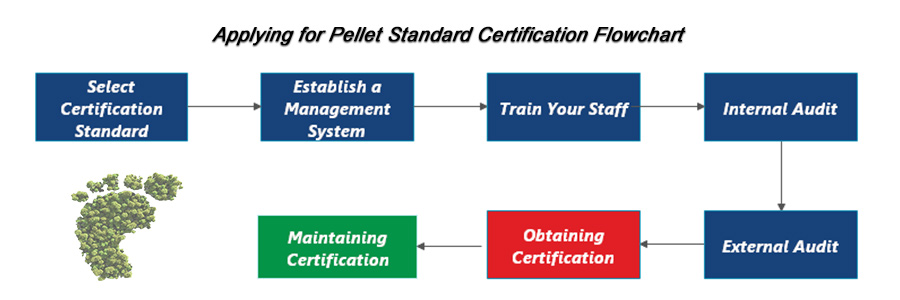

The Process of Obtaining Wood Pellet Standard Certification

Wood Pellet Quality Standard Certification Flowchart

The steps for certification vary slightly from one certification system to another. The following is a general certification process for your reference:

- Select Certification Standards and Prepare Documentation

Determine the applicable certification standards and then prepare the relevant documentation. These documents may include quality manuals, procedure documents, policy documents, training records, lab test records, traceability records of raw material sources, etc.

- Establish a Management System

Establish a management system that meets the requirements of the standard to ensure wood pellet product consistency, quality, and compliance.

- Train Your Staff

Ensure that your staff understands the requirements of the certification standard and can effectively implement the relevant procedures and processes.

- Internal Audit

Before applying for certification, an internal auditor usually carried out an internal audit to check documentation and actual operations.

- Selection of Certification Body for External Audit

Select an accredited, independent certification body, which will be responsible for conducting the external audit. The audit will cover management system documentation, records, and practices.

- Obtaining Certification and Maintaining Certification

After passing the audit, the certification body will issue certification and conduct periodic surveillance reviews.

GEMCO: Excellent Support for Making Top Rated Wood Pellets

At GEMCO, we understand the importance of adhering to strict quality assessment criteria. With nearly 30 years of experience in pellet machinery manufacturing, we are committed to providing our customers with solutions that enable them to produce top quality wood pellets.

We utilize advanced production processes and technology to ensure that wood pellets made GEMCO pellet mills meet and exceed industry standards. We offer a complete range of pellet machines, pelletizing systems, and auxiliary equipment to meet different production scales and requirements.

Contact us now for free consulting! Let us help you lead the way in wood pellet production.