Starting Organic Fertilizer Production with Biowaste

Organic fertilizer production is an important part of modern agriculture, promoting soil health and crop growth by converting organic waste into high-value fertilizers. With the rise of sustainable agriculture, the demand for organic fertilizers continues to grow, and more and more farmers and companies are focusing on the production and application of organic fertilizers and actively investing in commercial organic fertilizer production. In this feature, we will delve into various aspects of organic fertilizer production, aiming to provide investors in organic fertilizer plants with useful insights to help your organic fertilizer manufacturing plant achieve its profitability goals.

- Benefits of Horse Manure Pellet Machine for Fertilizer Production

- Cow Dung Pellet Making Machine: Transform Waste into Fertilizer

- Invest in a Sheep Manure Pellet Machine for Sustainable Fertilizer

- Top Advantages of Vertical Stainless Steel Fermentation Tanks

- Analysis of Organic Fertilizer Plant Business Plan Costs

- Get the Best Organic Manure Fertilizer Pellet Machine

- Making Fertilizer with Kitchen Waste Composting Machines

- Producing Chicken Manure Fertilizer with Pellet Machines

Diverse Sources of Organic Fertilizers and Their Benefits

Organic fertilizer is an important soil amendment that provides plants with the nutrients they need to grow. Organic fertilizers come from a wide variety of sources, far broader than we might think, including animal manure, plant residues, food waste, etc., each with its own unique nutrient composition and applicable crops.

| Organic Fertilizer Raw Material | Advantages | Function |

|---|---|---|

| Animal manure | Rich in nitrogen, phosphorus, potassium and other nutrients, easily available. | Promote plant growth, improve soil structure and enhance soil fertility. |

| Plant residues | Renewable resource, providing rich organic matter and reducing farm waste. | Increase soil organic matter content and enhance soil microbial activity. |

| Food Waste | Generated in large quantities, can be converted into organic fertilizer and reused as a resource when properly treated. | Provides rich nutrients, reduces landfill and improves soil health. |

| Industrial by-products | Rich in organic matter and nutrients, usually at low cost. | Improves soil fertility, recycles resources and reduces production waste. |

| Municipal Solid Waste | Municipal waste is abundant and has high potential for utilization. | Provides additional fertilizer for agriculture and promotes sustainable urban development. |

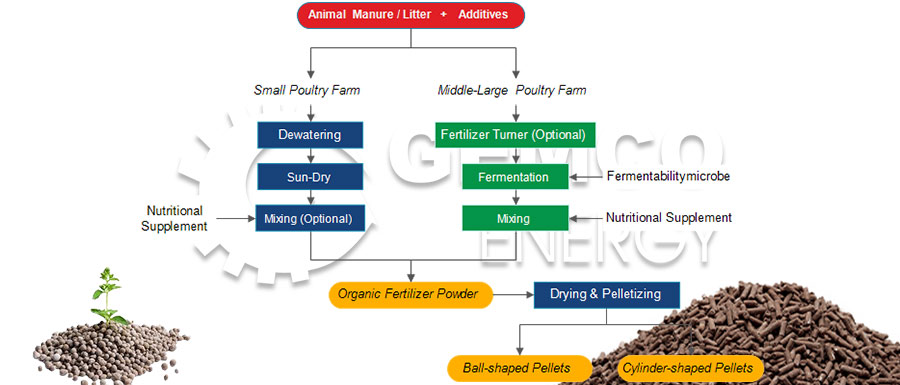

Organic Fertilizer Manufacturing Process and Equipment

The production of high quality organic fertilizer requires advanced equipment and processes. This is because the organic fertilizer making process, the type of raw materials, the way they are handled, and the quality of the final product are all directly affected by the performance of the organic fertilizer production machine and the organic fertilizer production process. Next, we will discuss the main steps and equipment in organic fertilizer production.

How to Make Organic Fertilizer Step by Step: Key Process Analysis

Examples of Common Organic Fertilizer Production Processes

- Raw Material Preparation

Collection of raw materials and removal of impurities and unsuitable parts for fermentation.

- Fermentation and Maturation

Fermentation is carried out at a temperature of 55-65°C for a period of 2-4 weeks, with regular turning of the piles (every 3-5 days) to ensure uniform fermentation. Then continue maturing under suitable conditions for 2-3 weeks to ensure further decomposition of organic matter and increase the stability of the fertilizer.

- Granulation (optional)

After aging, organic fertilizer can be produced into granular fertilizer through granulation process for easy transportation and application. The granulation process can be realized by the following methods:

Pressing pelletization: the mixed fertilizers are pressed into pellets through a pellet machine.

Roller granulation: a small amount of water is added to the roller and friction is used to shape the fertilizer particles.

- Drying and cooling

The granulated organic fertilizer needs to be dried and cooled to reduce the moisture and ensure the storage stability of the fertilizer. The drying temperature is generally 60-80°C.

- Packaging and Storage

The dried organic fertilizer can be packaged, and the storage conditions should be kept dry, cool ideal relative humidity between 30%-50% to prevent mold and deterioration.

Main Organic Fertilizer Production Equipment for Efficient Production

Choosing the right organic fertilizer manufacturing machine is an important step to optimize the making of organic fertilizer. Properly configured organic fertilizer processing equipment not only enhances production efficiency, but also improves the quality of the final product. Below are the main equipment used to produce organic fertilizer.

Main Equipment of a Complete Organic Fertilizer Making Line

- Crushing Machine

Used to crush raw materials into suitable particles for subsequent processing.

- Mixing Machine

Ensures uniform mixing of different raw materials for a more even distribution of nutrients.

- Fermentation Tank

Provides an ideal microbial fermentation environment to promote effective decomposition.

- Granulator (optional)

Organic fertilizer granules making machines are available in two main options: pellet mill (flat die pellet mill, ring die pellet mill) and drum granulator.

- Drying Machine

Helps to control the moisture content of the product and enhance the quality of the final organic fertilizer product.

Starting Your Organic Fertilizer Production with GEMCO

At GEMCO, we're more than just a supplier of organic fertilizer making machines. We're organic fertilizer companies' partner in green business profitability. With 25 years of industry experience and 35 technology patents, we provide organic fertilizer manufacturers with complete solutions from small to large scale to ensure organic fertilizer manufacturing business maximize return on investment.

Organic Fertilizer Fermentation Tank for Sale

Our organic fertilizer production plants help you convert waste into green organic fertilizers with their high capacity, low energy consumption and ease of operation. By choosing us to invest in an organic fertilizer production line, you will receive a tailor-made processing solution to meet your specific needs. Our professional team supports you every step of the way, from market analysis to after-sales service. Our goal is to make your investment simple and efficient.

Contact us today and let's start your organic fertilizer production journey towards a green and profitable business investment.